Understanding the Properties of Pure Nickel Sheets for Engineers: A Comprehensive Guide

Release time:

2026-01-20

Understanding the Properties of Pure Nickel Sheets for Engineers In the realm of metallurgy and materials science, pure nickel sheets have garnered significant attention due to their exceptional properties and versatility. As engineers, understanding these properties is crucial for selecting the appropriate materials for various applications. This comprehensive guide explores the key characteristi

Understanding the Properties of Pure Nickel Sheets for Engineers

In the realm of metallurgy and materials science, pure nickel sheets have garnered significant attention due to their exceptional properties and versatility. As engineers, understanding these properties is crucial for selecting the appropriate materials for various applications. This comprehensive guide explores the key characteristics, benefits, and applications of pure nickel sheets, equipping engineers with the knowledge needed to make informed decisions.

Table of Contents

- What is Pure Nickel?

- Chemical Properties of Pure Nickel Sheets

- Mechanical Properties of Pure Nickel

- Corrosion Resistance of Pure Nickel Sheets

- Thermal Properties and Conductivity

- Fabrication Techniques for Nickel Sheets

- Applications of Pure Nickel Sheets in Engineering

- Frequently Asked Questions

- Conclusion

What is Pure Nickel?

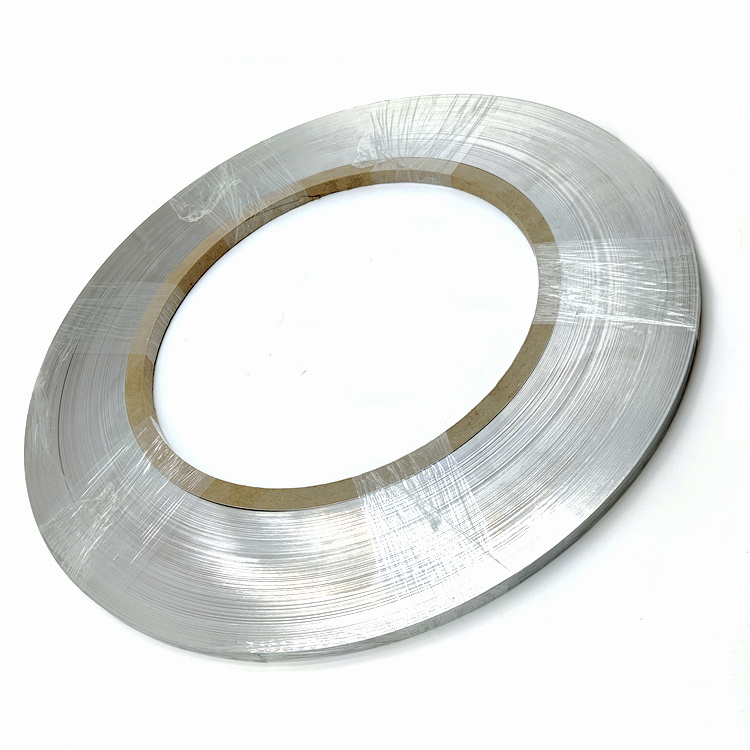

Pure nickel is a silvery-white metal known for its remarkable corrosion resistance and high-temperature stability. It is classified as a transition metal and is primarily derived from nickel ores through hydrometallurgical and pyrometallurgical processes. Nickel is often utilized in various industrial applications due to its excellent mechanical properties and resistance to oxidation and corrosion. In its pure form, nickel exhibits a high degree of ductility and malleability, making it an ideal material for sheet metal production.

Chemical Properties of Pure Nickel Sheets

The chemical properties of pure nickel sheets play a pivotal role in their usability within different environmental conditions. Nickel has a unique ability to resist oxidation, even at elevated temperatures, thanks to the formation of a protective oxide layer. This layer enhances its resistance to various corrosive environments, making pure nickel sheets suitable for use in chemical processing and marine applications.

Reactivity and Stability

Pure nickel is relatively unreactive compared to other metals. It does not readily corrode in neutral or alkaline solutions. However, it can react with strong acids and bases, which should be considered when using nickel sheets in specific chemical environments. Its stability and inertness contribute to its widespread use in environments where other metals might fail.

Mechanical Properties of Pure Nickel

When it comes to engineering applications, the mechanical properties of pure nickel sheets are of utmost importance. These properties include tensile strength, yield strength, elasticity, and hardness, all of which determine how the material will perform under load.

Tensile Strength and Yield Strength

Pure nickel exhibits high tensile strength, making it capable of withstanding significant loads without deformation. The yield strength of pure nickel is also considerable, allowing it to maintain its structural integrity under stress. This attribute is particularly beneficial for applications requiring durable materials that can endure harsh operating conditions.

Ductility and Malleability

One of the standout features of pure nickel is its exceptional ductility and malleability. These properties allow engineers to fabricate intricate shapes and components from nickel sheets without the risk of cracking or breaking. Ductility is especially important in applications such as electrical connectors and components where flexibility is crucial.

Corrosion Resistance of Pure Nickel Sheets

Corrosion resistance is a defining characteristic of pure nickel, and it significantly influences its applicability across various industries. The metal's ability to resist corrosion stems from its passive oxide layer, which forms naturally when exposed to air or moisture.

Applications in Corrosive Environments

Because of its excellent resistance to corrosion, pure nickel sheets are commonly used in environments that involve exposure to harsh chemicals, saline solutions, or extreme temperatures. Industries such as oil and gas, marine, and chemical processing frequently rely on nickel for components that must endure these conditions without degrading.

Thermal Properties and Conductivity

The thermal properties of pure nickel sheets are vital for applications in high-temperature environments. Nickel has a relatively high melting point of approximately 1455°C (2651°F), which allows it to maintain its integrity under extreme conditions.

Thermal Conductivity

In addition to its high melting point, pure nickel exhibits good thermal conductivity, making it suitable for applications in heat exchangers and other thermal management systems. Engineers often select nickel sheets for their ability to effectively transfer heat while maintaining structural stability.

Fabrication Techniques for Nickel Sheets

Understanding the fabrication techniques for pure nickel sheets is crucial for engineers looking to utilize this material effectively. Various methods are available for shaping, cutting, and joining nickel sheets, ensuring versatility in design and application.

Cutting and Shaping Techniques

Common methods for cutting nickel sheets include laser cutting, water jet cutting, and mechanical shearing. Each technique has its advantages and is selected based on the specific requirements of the project. For instance, laser cutting offers precision for complex shapes, while water jet cutting minimizes thermal distortion.

Joining Methods

Welding is a widely used joining technique for nickel sheets, with methods such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding being popular choices. These techniques allow for strong, durable joints that maintain the integrity of the material. Additionally, soldering and brazing are viable options for applications requiring lower heat input.

Applications of Pure Nickel Sheets in Engineering

The applications of pure nickel sheets are vast and diverse, spanning multiple industries due to their unique properties. Engineers leverage pure nickel in various forms, from structural components to specialized equipment.

Electrical Applications

Pure nickel sheets are commonly used in electrical applications, including battery terminals, connectors, and heating elements. Their excellent conductivity and resistance to corrosion make them ideal for ensuring reliable electrical connections and performance.

Industrial Equipment

In industrial settings, pure nickel sheets are often employed in the manufacturing of equipment such as heat exchangers, reactors, and piping systems. Their ability to withstand high temperatures and corrosive environments ensures longevity and efficiency in these demanding applications.

Aerospace and Automotive Industries

Within the aerospace and automotive sectors, pure nickel is utilized for components that require lightweight yet durable materials. Engine parts, fasteners, and exhaust systems benefit from the high strength and heat resistance of pure nickel sheets, contributing to improved performance and safety.

Frequently Asked Questions

1. What are the advantages of using pure nickel sheets over other metals?

Pure nickel sheets offer superior corrosion resistance, high tensile strength, and excellent thermal conductivity, making them ideal for demanding industrial applications.

2. Can pure nickel sheets be welded easily?

Yes, pure nickel can be welded using techniques such as TIG and MIG welding, which produce strong and durable joints.

3. Are there any limitations to using pure nickel sheets?

While pure nickel has many advantages, it can be more expensive than other materials, and its reactivity in strong acids and bases needs to be considered for specific applications.

4. How do I select the right thickness of pure nickel sheet for my application?

The thickness of the nickel sheet should be based on the specific mechanical and thermal requirements of your application, as well as the stresses it will encounter.

5. Is pure nickel recyclable?

Yes, pure nickel is fully recyclable, making it an environmentally friendly choice for engineers concerned about sustainability.

Conclusion

In summary, pure nickel sheets are an exceptional material choice for engineers due to their unique properties, including corrosion resistance, mechanical strength, and thermal conductivity. Their versatility allows for a wide range of applications across various industries, from electrical components to aerospace engineering. Understanding the properties and potential uses of pure nickel sheets is essential for making informed material selections in engineering projects. By leveraging the advantages of pure nickel, engineers can enhance the performance and longevity of their designs, leading to more efficient and sustainable solutions.

SEO:

Cheng Yuan

Alloy Material

We look forward to working with you to jointly promote the development of China's alloy material industry.

Telephone

Email us

For more information, please leave your message below.