Soft Magnetic Alloy

If you need customized products, Contact US !

Category

Tag list

Soft Magnetic Alloy

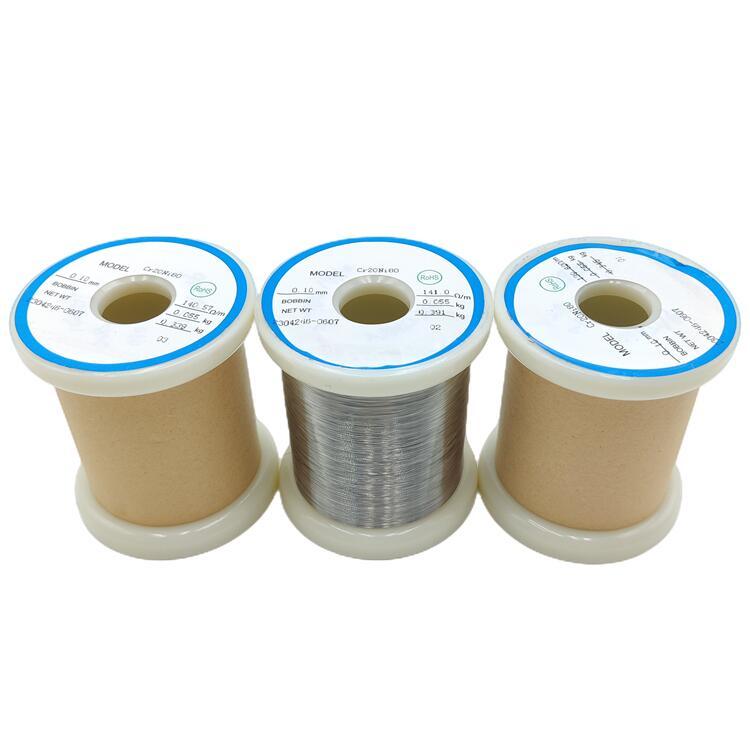

The product forms include wire, strip, plate, bar, wire mesh, powder, pipe, etc. Click to view.

Category

Tag list

- 详细描述

-

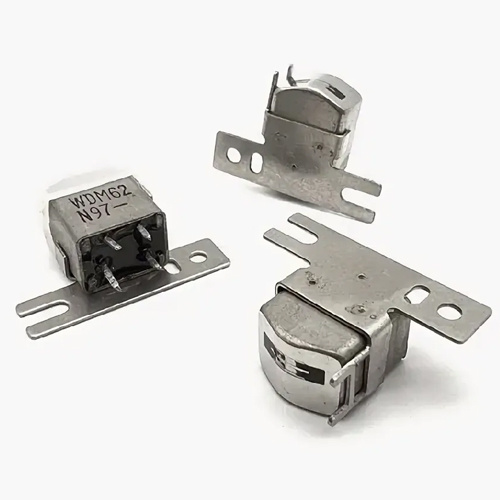

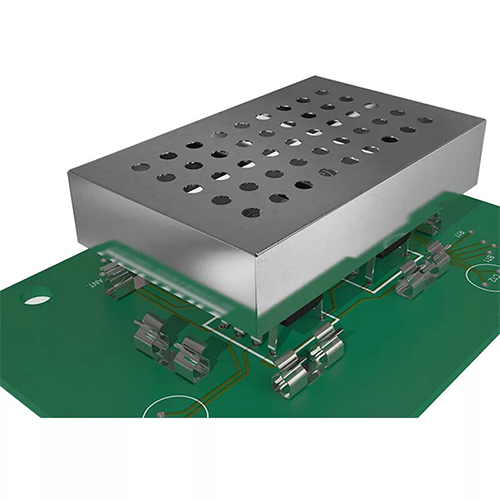

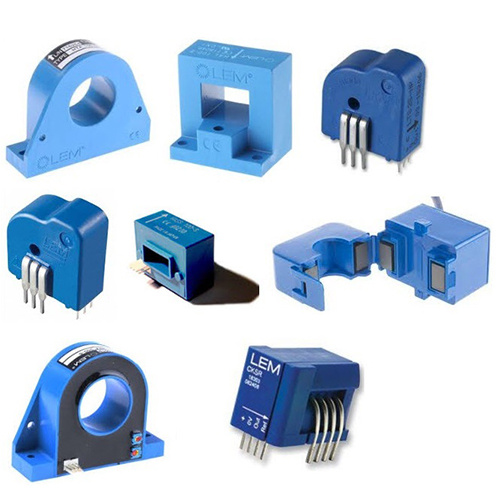

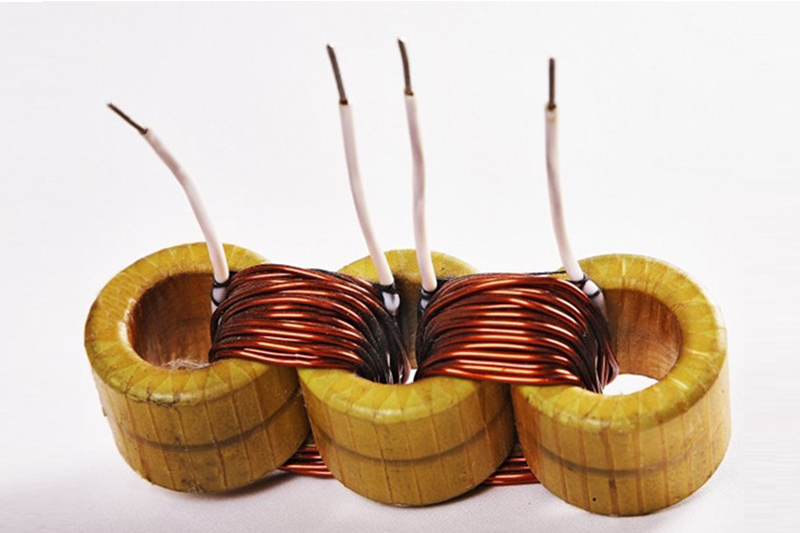

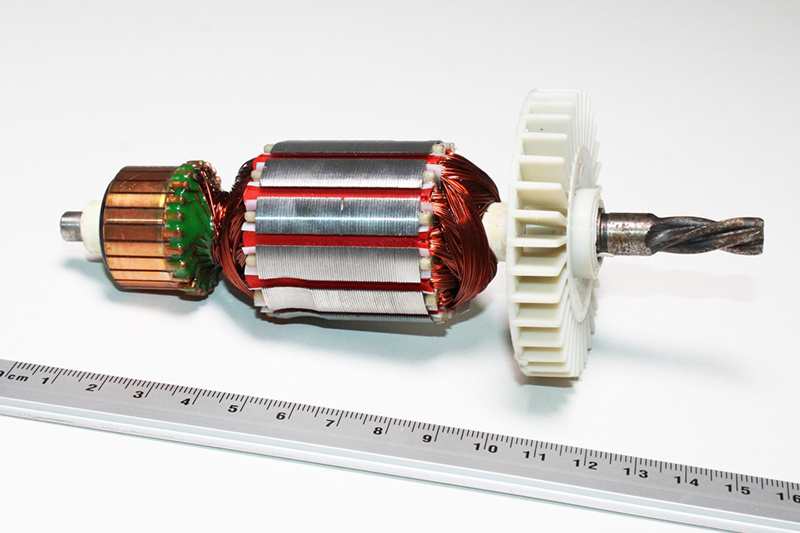

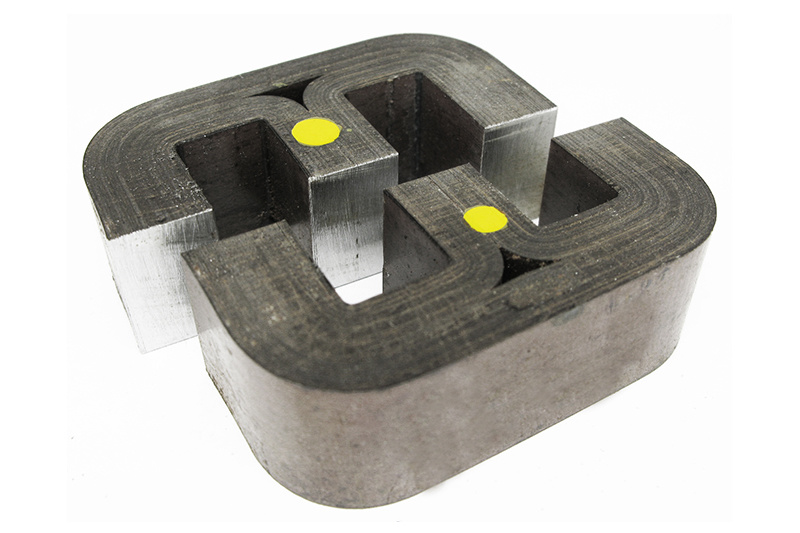

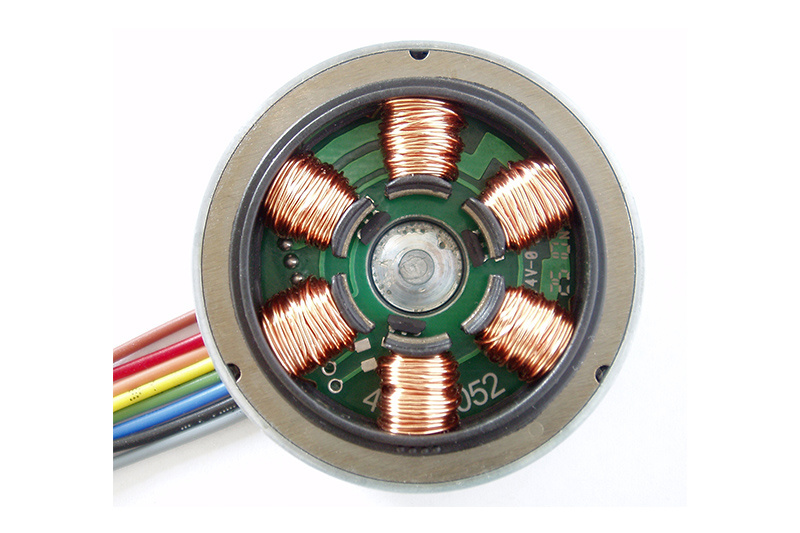

Product application

Soft Magnetic Alloy

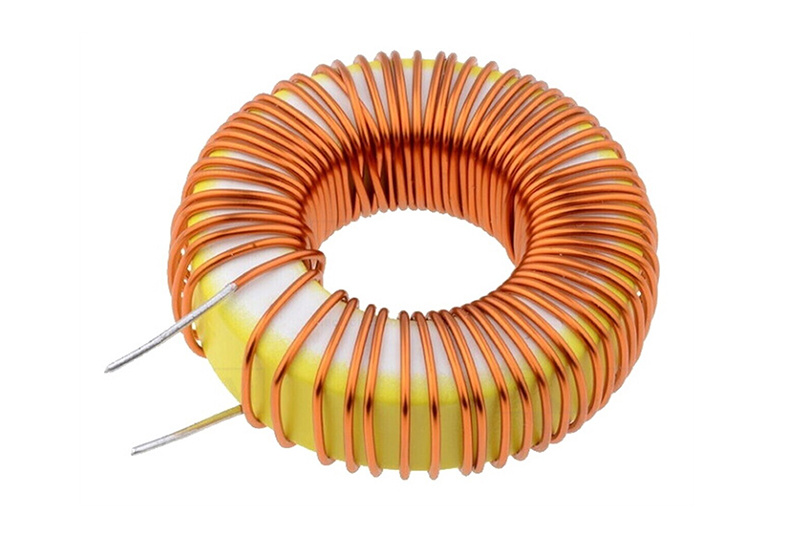

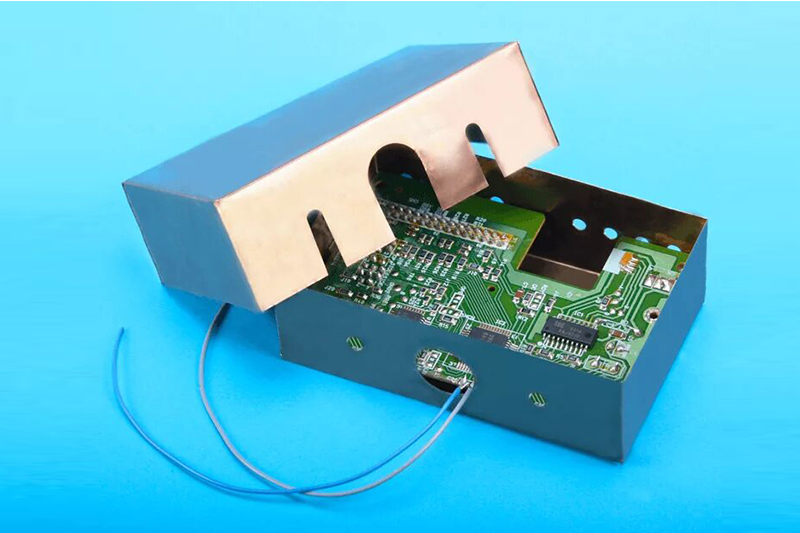

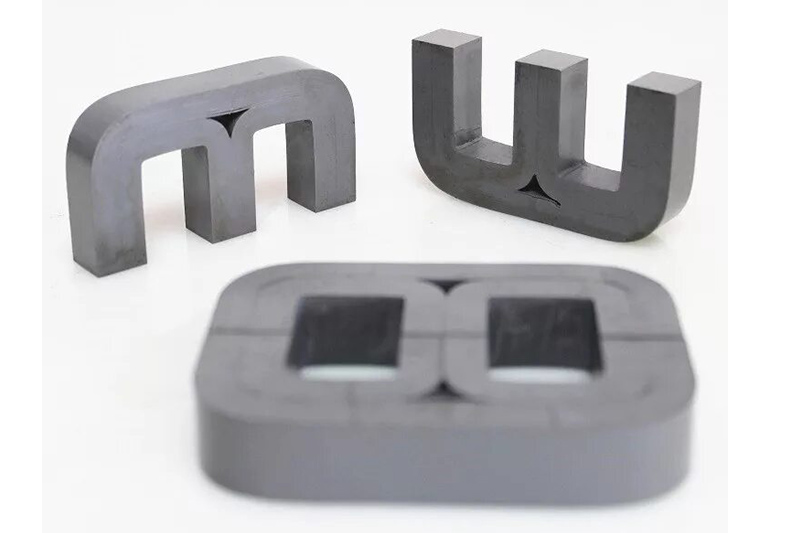

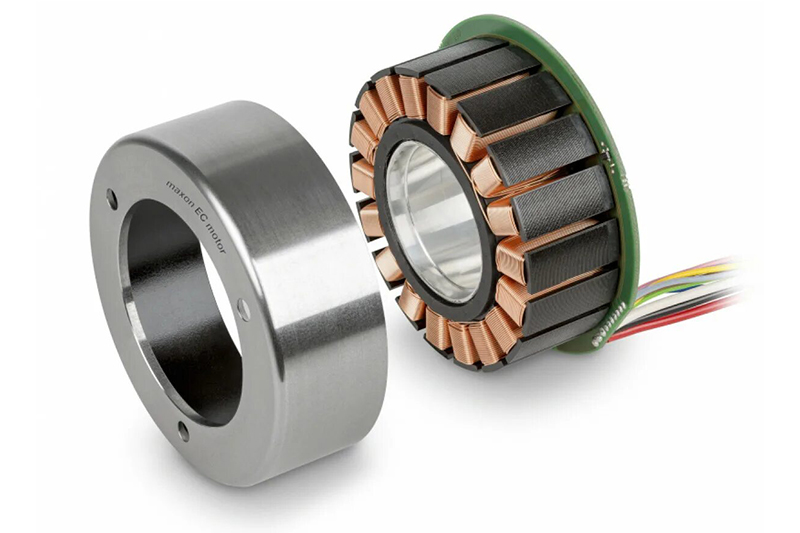

Soft magnetic alloys are materials with high magnetic permeability and low coercivity, allowing them to effectively guide and control magnetic fields within electromagnetic systems. This makes them crucial in applications such as transformers, motors, sensors, and electromagnetic shielding devices. These alloys can be easily demagnetized at very low magnetic field strengths, making them suitable for environments with frequent or rapid magnetic field changes. Common types of soft magnetic alloys include iron-nickel, iron-cobalt, iron-chromium, and iron-aluminum alloys, each possessing unique properties and extensively used in the electronics industry, telecommunications, automotive manufacturing, and aerospace.

Availability: We offer a range of soft magnetic alloys including grades 1J22, 1J27, 1J50, 1J54, 1J79, and 1J85, available in various forms such as cold-drawn wire, cold-rolled strip, hot-rolled flat, and hot-forged bar. Additionally, we provide customization services, capable of producing soft magnetic alloys in different sizes and shapes according to customer requirements.

Alloy Grades by country

Used Grade ГОСТ ASTM Japan Co50V2 49К2ФА Hiperco 50 SME SMEV Co27Fe 27КХ Hiperco27 27KX Ni50 50H Hy-Ra49 PB Ni50Cr14Si 50HXC Permalloy - Ni79Mo4 79HM Permalloy PC Ni80Mo5 81HMA Supermalloy - Chemical composition%

Iron-cobalt Grade C Mn Si P S Cr Ni Co Cu V Fe Not More Than 1J22 0.030 0.30 0.30 0.020 0.015 0.20 0.50 49.0~

51.0≤0.20 0.80~

1.80remainder 1J27 0.030 0.40 0.35 0.015 0.015 0.75 0.75 26.5~

28.5— ≤0.35 remainder Iron-nickel Grade C P S Cu Mn Si Cr Ni Co Mo Fe Not More Than 1J50 0.03 0.02 0.02 0.02 0.30-0.60 0.15-0.30 — 49.0-51.0 — — remainder 1J54 0.03 0.02 0.02 0.02 0.30-0.60 1.10-1.40 3.80-4.20 49.5-51.0 — — remainder 1J79 0.03 0.02 0.02 0.02 0.60-1.10 0.30-0.50 — 78.5-80.0 — 3.80-4.10 remainder 1J85 0.03 0.02 0.02 0.02 0.30-0.60 0.15-0.30 — 79.0-81.0 — 4.80-5.20 remainder Mechanical properties

Grade Hardness Tensile strength Yield Strength elongation Elastic modulus HV σb/MPa σs/MPa δ/% E/GPa Hard Soft Hard Soft Hard Soft Hard Soft 1J22 270 190 1325 490 - - 1 4 216 1J27 275 190 1150 550 - - 7 12 166 Grade HBS σb/MPa σs/MPa δ/% E/GPa Hard Soft Hard Soft Hard Soft Hard Soft 1J50 170 130 785 450 685 150 3 - 196 1J54 190 125 885 500 833 150 2 40 - 1J79 210 120 1030 560 980 150 3 50 206 1J85 - - - - - - - - - Supply form and specification

Grade Type Specification 1J22;1J27;1J50;1J54;1J79;1J85 Wire Diameter= 0.025mm~8 mm Strip Width= 5~400mm Thickness= 0.1~3.0 mm Foil Width= 5~120mm Thickness= 0.01~0.1 mm Bar Diameter= 3~300mm Length= 50~4000 mm Plate Thickness: 0.1~10 mm; Width: 50 ~1500mm; Length: 500 ~6000 mm Magnetic properties

Grade Product Category Static magnetic properties/T Coercivity

≤

A/mB400 B800 B1600 B2400 B4000 B8000 1J22 Cold rolled strip 1.70 2.00 2.10 2.15 2.20 2.25 110 Cold drawn wire

Hot rolled flat steel

Hot forged bar1.60 1.70 1.90 2.05 2.15 2.20 140 Grade Product Category Static magnetic properties/T Coercivity

≤

A/mB2400 B4000 B8000 B12000 B16000 1J27 Cold rolled strip 1.75 1.87 2.03 2.12 2.17 280 Cold drawn wire

Hot rolled flat steel

Hot forged bar1.05 1.10 1.75 1.95 2.10 300 Grade Product Category Class Thickness or diameter Magnetic permeability at 0.4 A/m magnetic field strength Maximum magnetic permeability Coercivity Saturation magnetic induction

mm μ0.4 μm mH/m A/m T ≧ ≦ ≧ 1J50 Cold rolled strip Ⅰ

0.040~0.049 2.2 30.0 25.0 1.50 0.05-0.09 2.5 38.0 16.0 1.50 0.10~0.19 2.9 40.0 14.4 1.50 0.20~0.34 3.5 50.0 11.2 1.50 0.35~0.50 4.0 62.5 9.6 1.50 0.51~1.00 3.8 62.5 9.6 1.50 1.10~2.00 3.6 56.3 9.6 1.50 2.10~3.00 3.5 56.3 9.6 1.50 Ⅱ 0.10~0.19 3.8 43.8 12.0 1.50 0.20~0.34 4.4 56.3 10.4 1.50 0.35~0.50 5.0 65.0 8.8 1.50 0.51~1.00 5.0 50.0 10.0 1.50 1.10~2.50 3.8 44.0 12.0 1.50 Ⅲ 0.05~0.20 12.5 75 4.8 1.52 Hot rolled flat steel 3~22 3.1 31.3 14.4 1.5 Hot forged bar 8~100 3.1 31.3 14.4 1.5 1J54 Cold rolled strip Ⅰ 0.005 1.25 10.0 56.0 1 0.01 1.60 12.5 40.0 1 0.02~0.04 1.9 20.0 20.0 1 0.05~0.09 2.5 25.0 16.0 1 0.10~0.19 3.1 31.3 12.0 1 0.20~0.34 3.8 35.0 9.6 1 0.35~0.50 4.0 40.0 8.0 1 0.51~1.00 3.8 40.0 8.0 1 Ⅱ 0.02~0.04 31 31 12 1 0.05~0.09 31 31 12 1 0.10~0.19 36 36 10 1 0.20~0.34 37.5 37.5 10 1 0.35~0.50 4.4 44 8 1 Hot rolled flat steel 0.35~1.00 2 20 20 1 Hot forged bar 8~100 2 20 20 1 Grade Product Category Class Thickness or diameter Magnetic permeability at 0.08 A/m magnetic field strength Maximum magnetic permeability Coercivity Saturation magnetic induction mm μ0.08 μm mH/m A/m T ≧ ≦ ≧ 1J79 Cold rolled strip Ⅰ 0.005 12.5 44.0 6.4 0.75 0.01 17

.587.5 4.8 0.75 0.02~0.04 20.0 112.5 4.0 0.75 0.05~0.09 22.5 137.5 2.8 0.75 0.10~0.19 25.0 162.5 2.0 0.75 0.20~ 0.34 28.0 225.0 1.6 0.75 0.35~1.00 31.0 250.0 1.2 0.75 1.10~2.00 28.0 225.0 1.6 0.75 2.10~3.00 26.3 187.5 2.0 0.75 Ⅱ 0.005 15.0 75.0 4.8 0.75 0.01 20.0 110. 0 3.2 0.75 0.02~0.04 22.5 125.0 2.4 0.75 0.05~0.09 25.0 150.0 2.0 0.75 0.10~0.19 27.5 187.5 1.6 0.75 0.20~0.34 31.3 250.0 1.2 0.75 0.35 32.5 275.0 0.96 0.75 Ⅲ 0.01 25.0 150.0 2.4 0.73 0.02~0.04 31.0 190.0 1.6 0.73 0.05~0.09 38.0 250.0 1.2 0.73 0.10~0.19 38.0 250.0 1.2 0.73 0.20~0.34 38.0 280.0 1.0 0.73 0.35 44.0 310.0 1.0 0.73 Hot rolled flat steel 3~30 25 125.0 2.4 0.75 Hot forged bar 8~120 25 125.0 2.4 0.75 1J85 Cold rolled strip Ⅰ 0.005~0.01 20.0 87.5 4.8 0.70 0.02~0.04 22.5 100.0 3.6 0.70 0.05~0.09 35.0 137.5 2.4 0.70 0.10~0.19 37.5 187.5 1.6 0.70 0.20~0.34 50.0 225.0 1.2 0.70 0.35~1.00 62.5 312.5 0.8 0.70 1.10~2.50 50.0 187.5 1.2 0.70 2.51~3.00 43.8 150.0 1.44 0.70 Ⅱ 0.02~0.04 37.5 137.5 2.4 0.70 0.05~0.09 50.0 175.5 1.6 0.70 0.10~0.19 62.5 225.0 1.2 0.70 0.20~0.34 75.0 250.0 1.0 0.70 0.35 68.8 325.0 0.7 0.70 Hot rolled flat steel 3~22 37.5 125.0 1.6 0.70 Hot forged bar 8~100 37.5 125.0 1.6 0.70 Heat treatment system

Grade Heating temperature/℃ Insulation time /h Cooling 1J22 850~900 3~6 Cool at a rate of 50°C/h to 100°C/h to 750°C, then cool to below 300°C at a rate of 180°C/h to 240°C/h before exiting the furnace. 1100±10 3~6 Cool at a rate of 50°C/h to 100°C/h to 850°C and hold for 3 hours, then cool to 700°C at a rate of 30°C/h, followed by cooling to below 300°C at a rate of 200°C/h before exiting the furnace. 850±10 4 Cool at a rate of 50°C/h to 750°C and hold for 3 hours, then cool to below 300°C at a rate of 200°C/h. Begin applying a direct magnetic field of 1200 A/m to 1600 A/m during the hold at 750°C. 1J27 850±20 3~6 Cool at a rate of 100°C/h to 200°C/h to 500°C, then cool to below 200°C at any desired rate before exiting the furnace. 1J50 1100~1150 3~6 Cool at a rate not exceeding 200°C/h to 600°C, then cool to 300°C at a rate not less than 400°C/h before exiting the furnace. 1J54 1100~1150 3~6 Cool at a rate not exceeding 200°C/h to 400°C to 500°C, then cool to 200°C at a rate not less than 400°C/h before exiting the furnace. 1J79 1100~1150 3~6 Cool at a rate not exceeding 200°C/h to 600°C, then cool to 300°C at a rate not less than 400°C/h before exiting the furnace. 1J85 1100~1200 3~6 Cool at a rate of 100°C/h to 200°C/h to 500°C to 600°C, then cool to 300°C at a rate not less than 400°C/h before exiting the furnace.

Contact us so we can better understand you

Every customer has their own needs, their own standards to adhere to and their own projects with unique specifications. Cheng Yuan is a partner in finding the right solution first time.

Ask a question, request information or enquire whichever way best suits you. Live chat with an expert, use any of our forms or contact us by phone or email.

Related Products

Cheng Yuan

Alloy Material

We look forward to working with you to jointly promote the development of China's alloy material industry.

Telephone

Email us

For more information, please leave your message below.