Corrosion Resistant Alloy

If you need customized products, Contact US !

Category

Tag list

Corrosion Resistant Alloy

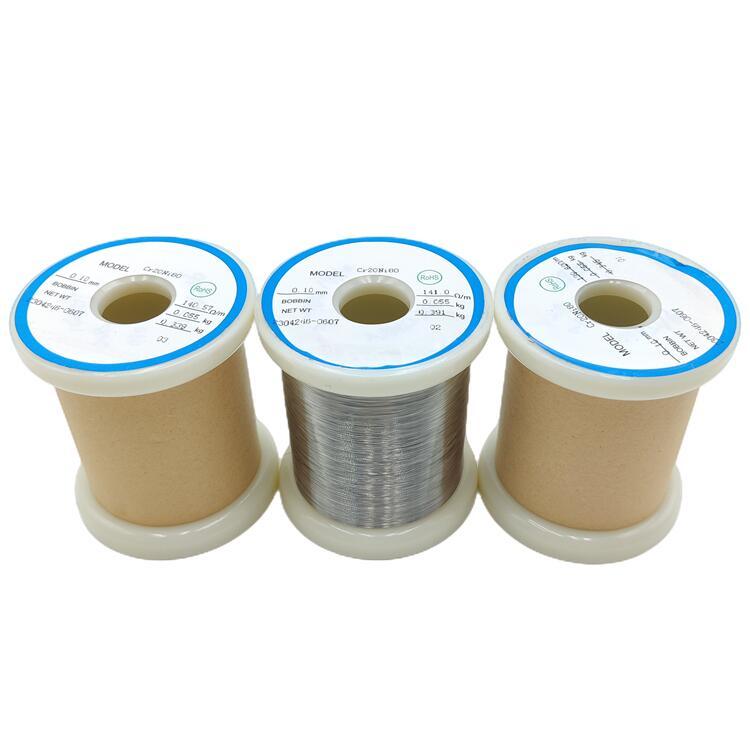

The product forms include wire, strip, plate, bar, wire mesh, powder, pipe, etc. Click to view.

Category

Tag list

- 详细描述

-

Product application

Corrosion Resistant Alloy

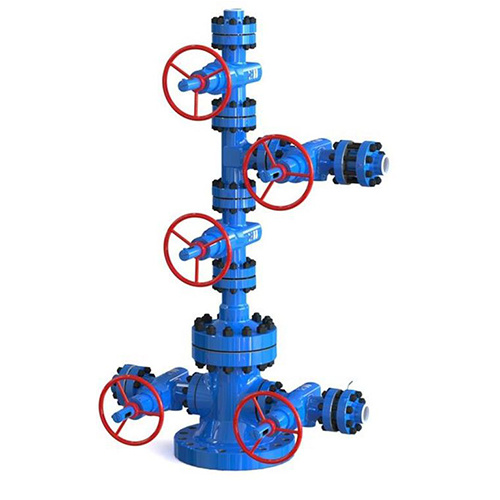

Corrosion-resistant alloys are a type of metal materials specially designed to resist various corrosive environments (such as chemical corrosion, electrochemical corrosion, high temperature oxidation, etc.). They generally have excellent corrosion resistance and are widely used in chemical and petrochemical industries (strong acids, strong alkalis, high temperatures, high pressures, etc.), oil and gas industries (sour gas wells, offshore platforms, pipelines, etc.), marine engineering (seawater corrosion, deep-sea mining, etc.), electric power (nuclear power, thermal power, etc.), aerospace and other fields.

Chemical composition %

Grade Chemical composition% C Cr Ni Fe Mo W Co Cu Al Ti Nb V N Si Mn P S Other elements Incoloy 800 ≤0.10 19.0~ 23.0 30.0~ 35.0 ≥39.5 — — — ≤0.75 0.15~ 0.60 0.15~ 0.60 — — — ≤ 1.00 ≤ 1.50 ≤ 0.030 ≤ 0.015 一 Incoloy 800H 0.05~ 0.10 19.0~ 23.0 30.0~ 35.0 ≥ 39.5 一 一 — ≤ 0.75 0.15~ 0.60 0.15~ 0.60 一 一 一 ≤ 1.00 ≤ 1.50 ≤ 0.030 ≤ 0.015 一 Incoloy 800HT 0.06~ 0.10 19.0~ 23.0 30.0~ 35.0 ≥ 39.5 一 一 一 ≤ 0.75 0.15~ 0.60 0.15~ 0.60 一 一 一 ≤ 1.00 ≤ 1.50 ≤ 0.030 ≤ 0.015 Al+Ti:

0.85~1.20Incoloy 825 ≤ 0.05 19.5~ 23.5 38.0~ 46.0 ≥ 22.0 2.5~ 3.5 — — 1.5~ 3.0 ≤ 0.20 0.60~ 1.20 — — — ≤ 0.50 ≤ 1.00 ≤ 0.030 ≤ 0.030 Incoloy 925 ≤ 0.030 19.5~ 22.5 42.0~ 46.0 ≥ 22.0 2.5~ 3.5 一 一 1.5~ 3.0 0.1~ 0.5 1.9~ 2.4 ≤ 0.5 — 一 ≤ 0.50 ≤ 1.00 ≤ 0.030 ≤ 0.030 一 Inconel 600 ≤ 0.15 14.0~ 17.0 ≥ 72.0 6.0~ 10.0 — 一 一 ≤ 0.50 — — 一 一 一 ≤ 0.50 ≤ 1.00 ≤ 0.030 ≤ 0.015 一 Inconel 601 ≤ 0.10 21.0~ 25.0 58.0~ 63.0 Bal. 一 一 一 ≤ 1.00 1.00~ 1.70 — — — — ≤ 0.50 ≤ 1.00 ≤ 0.030 ≤ 0.015 一 Inconel 690 ≤ 0.05 27.0~ 31.0 ≥ 58.0 7.0~ 11.0 一 — — ≤ 0.50 — — 一 一 ≤ 0.50 ≤ 0.50 ≤ 0.030 ≤ 0.015 一 Hastelloy C ≤ 0.08 14.5~ 16.5 Bal. 4.0~ 7.0 15.0~ 17.0 3.0~ 4.5 ≤ 2.5 — — 一 一 ≤ 0.35 一 ≤ 1.00 ≤ 1.00 ≤ 0.040 ≤ 0.030 — Hastelloy C276 ≤ 0.010 14.5~ 16.5 Bal. 4.0~ 7.0 15.0~ 17.0 3.0~ 4.5 ≤ 2.5 一 一 一 一 ≤ 0.35 一 ≤ 0.08 ≤ 1.00 ≤ 0.040 ≤ 0.030 — Hastelloy C-4 ≤ 0.015 14.0~ 18.0 Bal. ≤ 3.0 14.0~ 17.0 — ≤ 2.0 — — ≤ 0.70 — — ≤ 0.08 ≤ 1.00 ≤ 0.040 ≤ 0.030 一 Inconel 625 ≤ 0.10 20.0~ 23.0 Bal. ≤ 5.0 8.0~ 10.0 — ≤ 1.0 — ≤ 0.40 ≤ 0.40 3.15~ 4.15 — — ≤ 0.50 ≤ 0.50 ≤ 0.015 ≤ 0.015 — Hastelloy C-22 ≤ 0.015 20.0~ 22.5 Bal. 2.0~ 6.0 12.5~ 14.5 2.5~ 3.5 ≤ 2.50 — — — — ≤ 0.35 一 ≤0.08 ≤ 0.50 ≤ 0.020 ≤ 0.020 — Hastelloy X 0.05~ 0.15 20.5~ 23.0 Bal. 17.0~ 20.0 8.0~ 10.0 0.20~ 1.00 0.50~ 2.50 — 一 一 一 一 一 ≤ 1.00 ≤ 1.00 0.04 0.03 一 HAYNES 230 0.05~ 0.15 20.0~ 24.0 Bal. ≤ 3.0 1.0~ 3.0 13.0~ 15.0 ≤ 5.0 ≤ 0.50 一 一 一 一 0.25~ 0.75 0.30~ 1.00 0.030 0.015 La:0.005~0.050 B:≤0.015 Hastelloy C-2000 ≤ 0.010 22.0~ 24.0 Bal. ≤ 3.0 15.0~ 17.0 一 ≤ 2.0 1.3~ 1.9 ≤ 0.50 一 一 一 一 ≤ 0.08 ≤ 0.50 ≤ 0.025 ≤ 0.010 一 Inconel X750 ≤ 0.08 14.0~ 17.0 ≥ 70.0 5.0~ 9.0 — 一 ≤ 1.0 ≤ 0.50 0.40~ 1.00 2.25~ 2.75 0.70~ 1.20 — — ≤ 0.50 ≤ 1.00 — ≤ 0.010 Ni=Ni+Co; Nb=Nb+Ta Monel 400 ≤ 0.30 — ≥ 63.0 ≤ 2.5 — — — 28.0~ 34.0 — — — — 一 ≤ 0.50 ≤ 2.00 一 ≤ 0.024 — Monel K500 ≤ 0.25 一 ≥ 63.0 ≤ 2.0 一 一 一 27.0~ 33.0 2.30~ 3.15 0.35~ 0.85 — — 一 ≤ 0.50 ≤ 1.50 ≤ 0.010 一 Mechanical properties for rods

Grade Recommended Heat Treatment Temperature/℃ Yield Strength

Rpo.2/MPaTensile strength Rm/MPa Relative elongation A/% Not less Incoloy 800 1000~1060 205 515 30 Incoloy 800H 1100~1170 170 450 30 Incoloy 800HT 1120~1170 170 450 30 Incoloy 825 1000~1050 240 590 30 Incoloy 925 1010~1065 517 241 35 Inconel 600 1000~1050 240 550 30 Inconel 601 1100~1150 195 550 30 Inconel 690 1000~1050 240 550 30 Hastelloy C 1160~1210 315 690 30 Hastelloy C276 1150~1200 285 690 40 Hastelloy C-4 1050~1100 275 690 40 Inconel 625 1100~1150 275 690 30 Hastelloy C-22 1100~1150 310 690 45 Monel 400 800~982 170 480 35 Supply form and specification

Form Specification Wire Diameter=0.025~10 mm Strip Thickness=0.05~3mm Width=5~250mm Sheet/ Plate Thickness=1~50mm Width=5~1500mm Bar Diameter=3~400 мм Length=20~6000mm Pipe Diameter=3~400 мм Length=20~6000mm

Contact us so we can better understand you

Every customer has their own needs, their own standards to adhere to and their own projects with unique specifications. Cheng Yuan is a partner in finding the right solution first time.

Ask a question, request information or enquire whichever way best suits you. Live chat with an expert, use any of our forms or contact us by phone or email.

Related Products

Cheng Yuan

Alloy Material

We look forward to working with you to jointly promote the development of China's alloy material industry.

Telephone

Email us

For more information, please leave your message below.