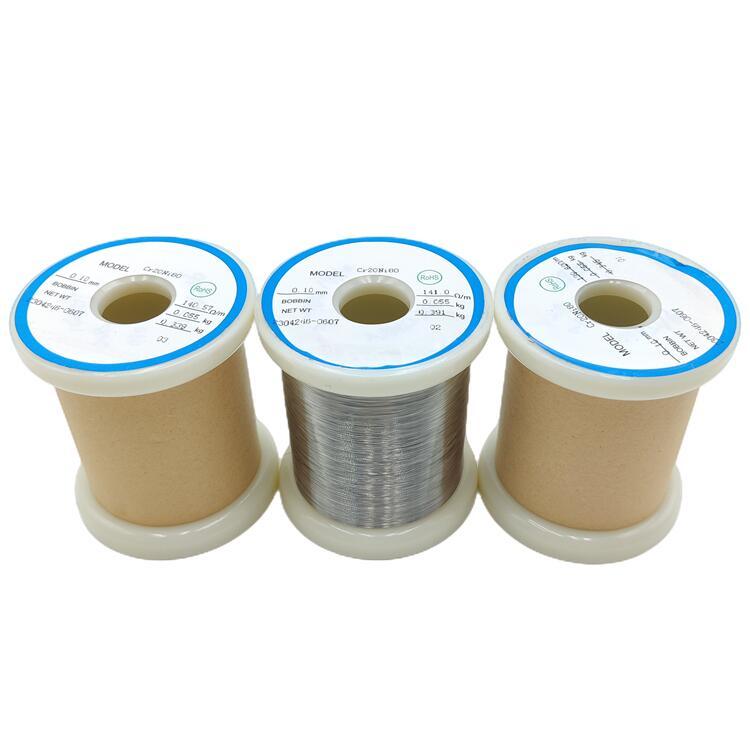

Strand Wire

This form can produce heating alloys, pure nickel alloys, high-temperature alloys, soft magnetic alloys, expansion alloys, corrosion-resistant alloys and stainless steel materials, etc. Click to view.

- 详细描述

-

Cheng Yuan Alloy performs inspections at all stages of production and our testing equipment verifies wire/strip/sheet/rod/tube/section tolerances, surface quality, roundness, strength properties and stress required to cause fracture.

Number of strands

Structure

Features

Common Applications

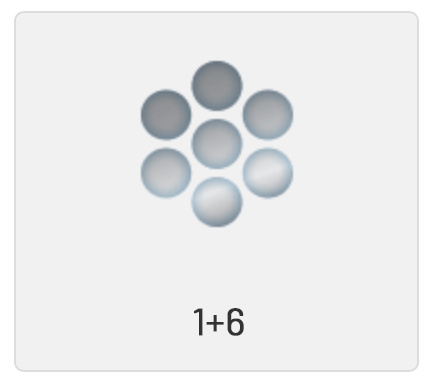

7

1+6

Simple, moderately soft

Low voltage cables, low power leads

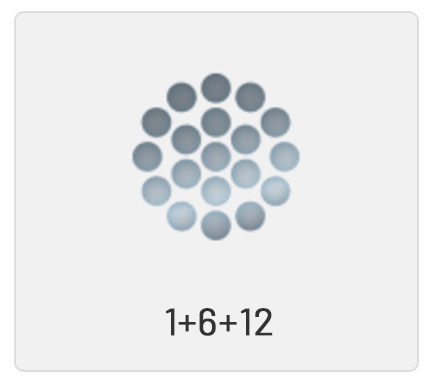

19

1+6+12

Very common, good softness

Battery leads, heaters, brush wires, etc.

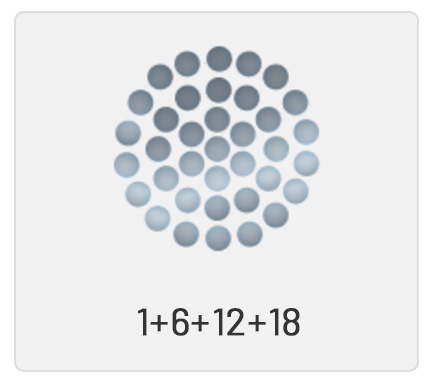

37

1+6+12+18

High flexibility and uniform current carrying capacity

Instrument cables, welding cables

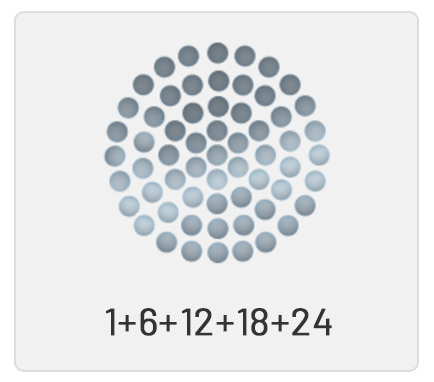

61

1+6+12+18+24

Higher flexibility and conductivity

Highly flexible connection, industrial high-end cable

Design considerations for selecting the number of shares

Considerations

Explanation

Softness

The more strands and the thinner the monofilament, the softer it is.

Mechanical strength

Fewer strands, larger wire diameter, higher tensile strength, but reduced softness

Current carrying

The total cross-sectional area determines the main conductivity, and the number of strands affects heat dissipation and skin effect.

Manufacturing Cost

More strands means increased manufacturing complexity and cost

Why is 19 strands commonly used?

Stable structure: 1+6+12 is a typical three-layer concentric twist, geometrically balanced

Considering both cost and flexibility: softer than 7-strand and cheaper than 37-strand

Commonly used in high conductive materials such as Nickel wire, Copper wire, Nichrome wire, FeCrAl wire, etc.

We can do more, please let us know your requirements.

Each spool contains one continuous length of wire. In most cases we can split your order into coils of lower weight (please ask for specifics).

Each spool is tested for alloy material identification. Mechanical testing is performed on each spool or as per our sampling plan, depending on the number of spools.

All spools are labeled and packed in appropriate cartons or wooden boxes depending on the chosen mode of transport.

Related Products

Request a Quote

We will contact you within 30 minutes. Please pay attention to your email.

Cheng Yuan

Alloy Material

We look forward to working with you to jointly promote the development of China's alloy material industry.

Telephone

Email us

For more information, please leave your message below.