Superalloy

If you need customized products, Contact US !

Category

Tag list

Superalloy

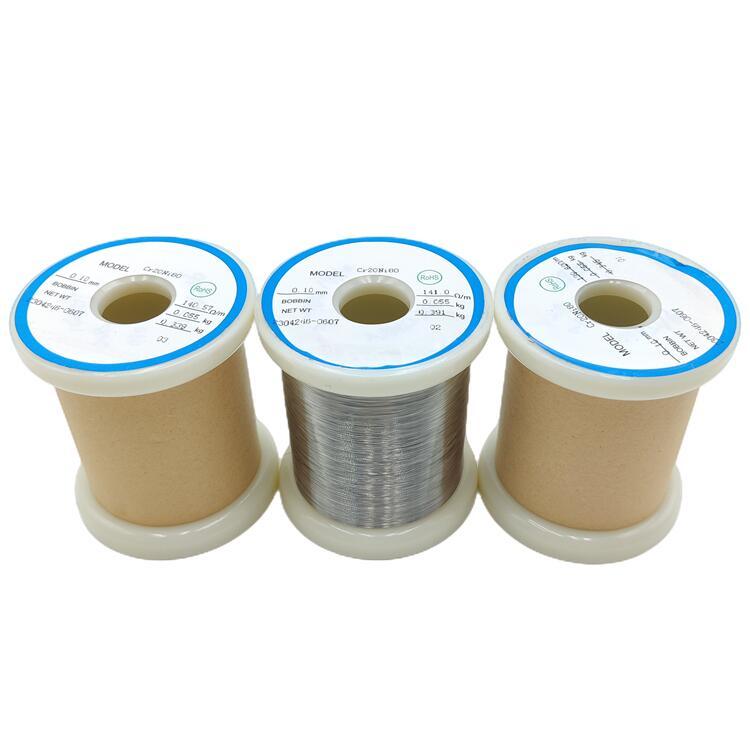

The product forms include wire, strip, plate, bar, wire mesh, powder, pipe, etc. Click to view.

Category

Tag list

- 详细描述

-

Product application

Heat-resistant alloy / Superalloys

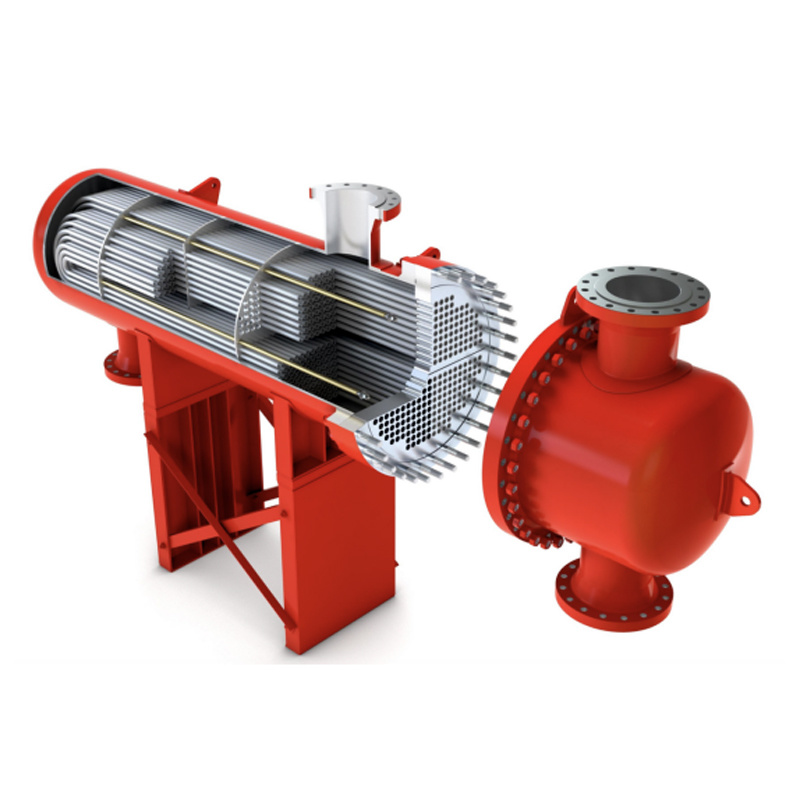

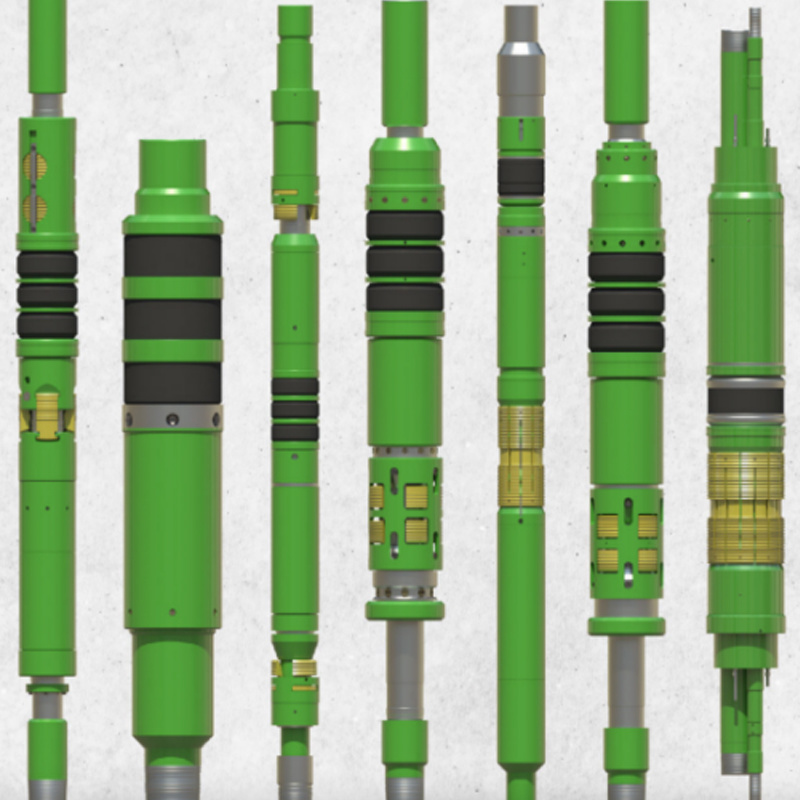

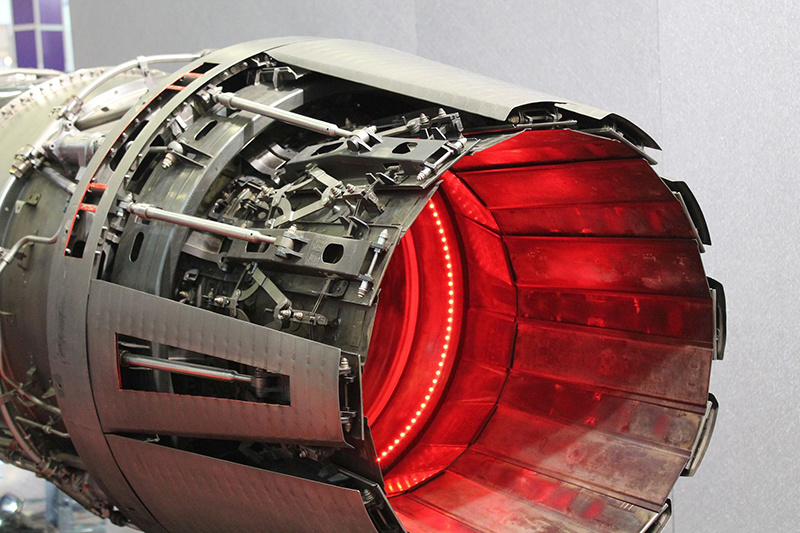

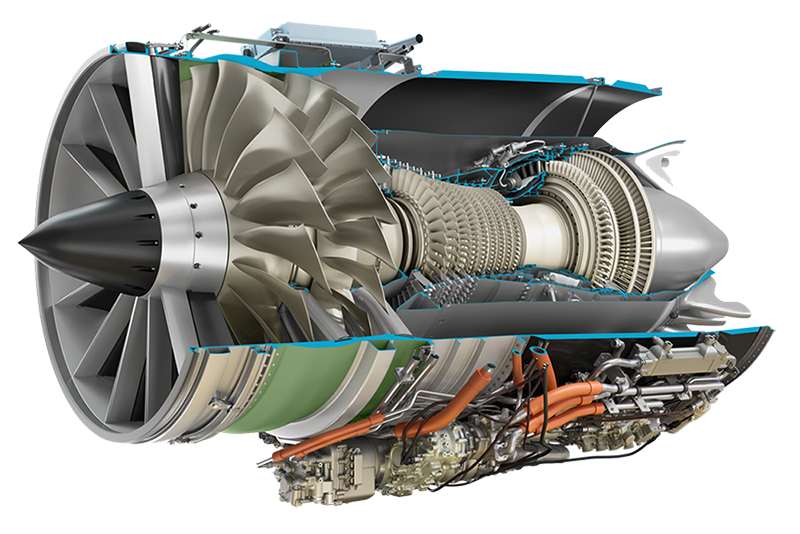

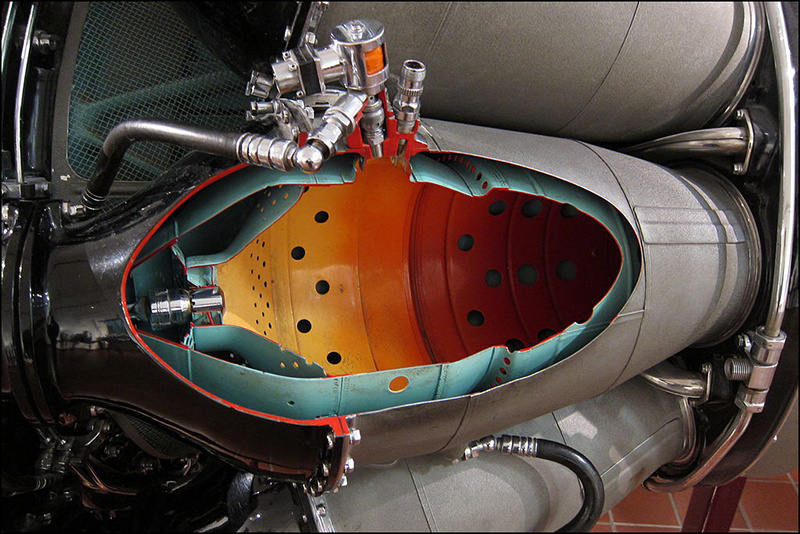

Heat-resistant alloy refers to a type of iron-nickel-cobalt-based metal material that can work at high temperatures above 600 ° C and under certain loads for a long time, and has high heat resistance, good antioxidant ability; and anti-corrosion property, good fatigue performance, fracture toughness and other comprehensive properties. Heat-resistant alloy has a single austenite structure, has good structural stability and reliable operation at various temperatures. Based on the above performance characteristics and the high alloying degree of heat-resistant alloys, they are also called "superalloys" and are an important material widely used in aviation, aerospace, petroleum, chemical industry and ships. According to the matrix elements, heat-resistant alloys are divided into iron, nickel, cobalt, etc. The use temperature of iron-based heat-resistant alloys can generally reach 750 ~ 780 ° C. For high-temperature-resistant parts used at higher temperatures, nickel-based and refractory metal alloys are applied. Nickel-based heat-resistant alloys occupy a particularly important position in the whole field of heat-resistant alloys. They are widely used in aircraft jet engines (such as turbine blades, combustion chambers, turbine disks), various industrial gas turbines (such as turbine blades and guide vanes, combustion chambers), nuclear power (such as heat exchangers), pressure vessels (such as cracking furnaces, chemical reactors, etc.) and other components.

Chemical composition %

Grade C Cr Ni Co W Mo Al Ti Fe Nb La Mg V B Zr Ce Si Mn P S Cu Inconel600 ≤0.15 14

-

17≥72 - - - ≤0.35 ≤0.5 6

-

10≤1 - - - - - - ≤0.5 ≤1 ≤0.04 ≤0.015 ≤0.5 InconelX-750 ≤0.08 14

-

17≥70 ≤1 - - 0.4

-

12.25-

2.755

-

9Nb+Ta

0.7

-

1.2- - - - - - ≤0.5 ≤1 ≤0.015 ≤0.01 ≤0.5 Inconel 718 ≤0.08 17

-

2150

-

55≤1 - 2.8

-

3.30.2

-

0.80.65

-

1.15Bal. 4.75

-

5.5- ≤0.01 - ≤0.006 - - ≤0.35 ≤0.35 ≤0.015 ≤0.015 ≤0.3 Nimonic80A 0.04-

0.118-21 Bal. ≤2 - - 1-1.8 1.8-2.7 ≤1.5 - - - - ≤0.0001 ≤0.0005(Ag) ≤0.002(Pb) ≤0.8 ≤0.4 ≤0.02 ≤0.015 ≤0.2 Waspalloy 0.03-0.1 18-21 Bal. 12-15 - 3.5-5 1.2-1.6 2.75-3.25 ≤2 ≤0.0025(As) ≤0.012(Sn) ≤0.0025(Sb) ≤0.0003(Se) 0.003-0.01 0.02-0.08 ≤0.0005(Pb) ≤0.15 ≤0.1 ≤0.015 ≤0.015 ≤0.1 Udimet500 ≤0.12 18-20 Bal. 15-20 - 3-5 2.75-3.25 2.75-3.25 ≤4 - - - - 0.003-0.008 ≤0.06 ≤0.001(Pb) ≤0.75 ≤0.75 ≤0.015 ≤0.015 ≤0.1 MP159 ≤0.04 18-20 Bal. 34-38 - 6-8 0.1-0.3 2.5-3.25 8-10 0.25-0.75 - - ≤0.03 - - ≤0.2 ≤0.2 ≤0.02 ≤0.01 - Mechanical properties

Grade Heat treatment Tensile strength Yield strength Relative elongation Hardness Constantly applied voltage σb/MPa σ0.2/MPa δ/% - σb/MPa δ/% ч Inconel600 1020-1040℃, air cooling 20℃

≥550900℃

≥95- 20℃

≥35900℃

≥40- - - - InconelX-750 720-740℃ * 8h, fast cooling

(55℃/h),

610-630℃ * 8h,

air cooling20℃

≥1105- - 20℃

≥1220℃

≥30HRC- - - Inconel 718 940-960℃, air cooling,

710-730℃ * 8.0-8.5 h,

rapid cooling

(40-60℃/h)

615-620℃ * 8.0-8.5 h,

air cooling20℃

≥1240650℃

≥1000- - 20℃

≥12650℃

≥520℃

≥36HRC650℃

655- 650℃

≥23Nimonic80A ASTM 1000-1300 ≥600 ≥17 20℃

≥260HB750℃

310≥4 ≥100 Waspalloy ASTM ≥1200 ≥830 ≥15 20℃

298-390HBS- - - Udimet500 ASTM ≥1100 ≥750 ≥10 20℃

≥350HV870℃

215≥9 ≥50 MP159 ASTM 20℃

≥1795595℃

≥141520℃

≥1725595℃

≥131020℃

≥6595℃

≥520℃

≥44HRC650℃

965≥5 ≥23 Regarding heat treatment, we can adjust it according to your method.

Supply form and specification

Form Specification Wire Diameter=0.025~10 mm Strip Thickness=0.05~3mm Width=5~250mm Sheet/ Plate Thickness=1~50mm Width=5~1500mm Bar Diameter=3~400 мм Length=20~6000mm Pipe Diameter=3~400 мм Length=20~6000mm Ring According to customer requirements

Contact us so we can better understand you

Every customer has their own needs, their own standards to adhere to and their own projects with unique specifications. Cheng Yuan is a partner in finding the right solution first time.

Ask a question, request information or enquire whichever way best suits you. Live chat with an expert, use any of our forms or contact us by phone or email.

Related Products

Cheng Yuan

Alloy Material

We look forward to working with you to jointly promote the development of China's alloy material industry.

Telephone

Email us

For more information, please leave your message below.