Expansion Alloy

If you need customized products, Contact US !

Category

Tag list

Expansion Alloy

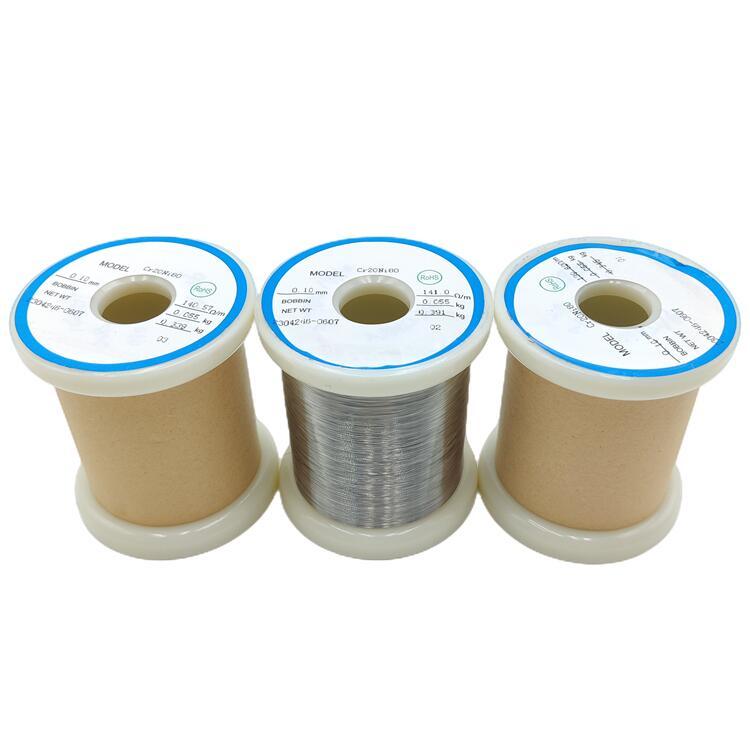

The product forms include wire, strip, plate, bar, wire mesh, powder, pipe, etc. Click to view.

Category

Tag list

- 详细描述

-

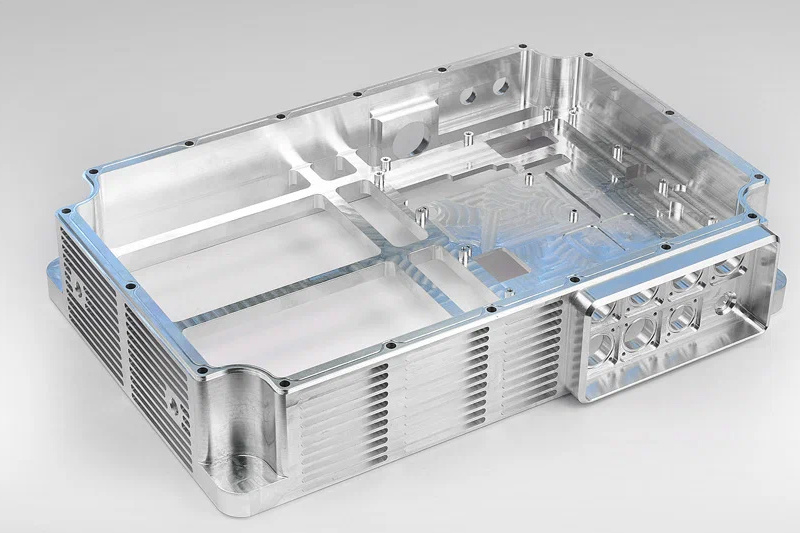

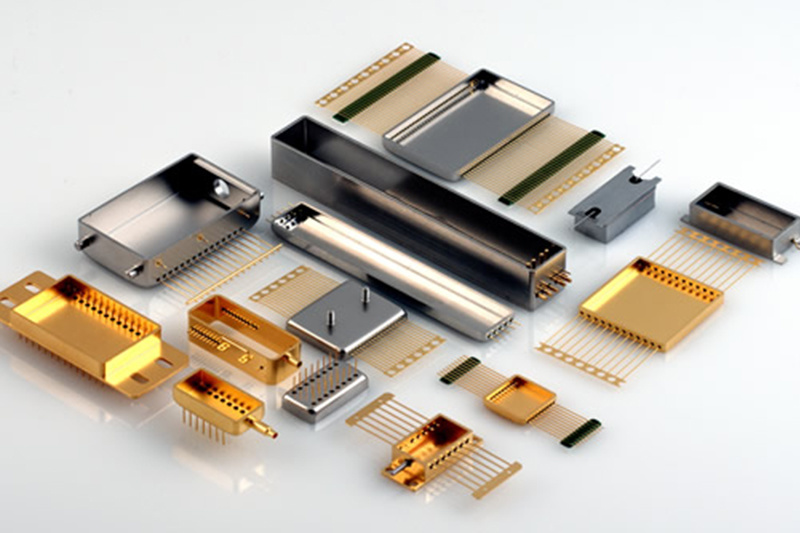

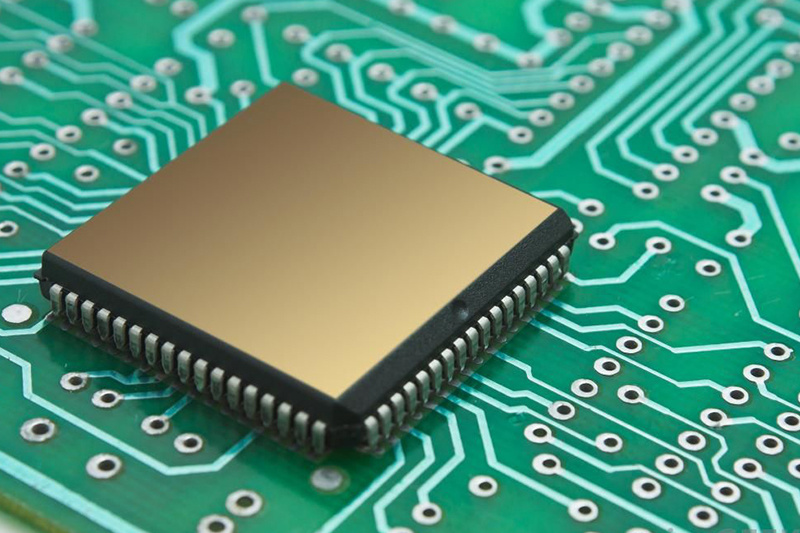

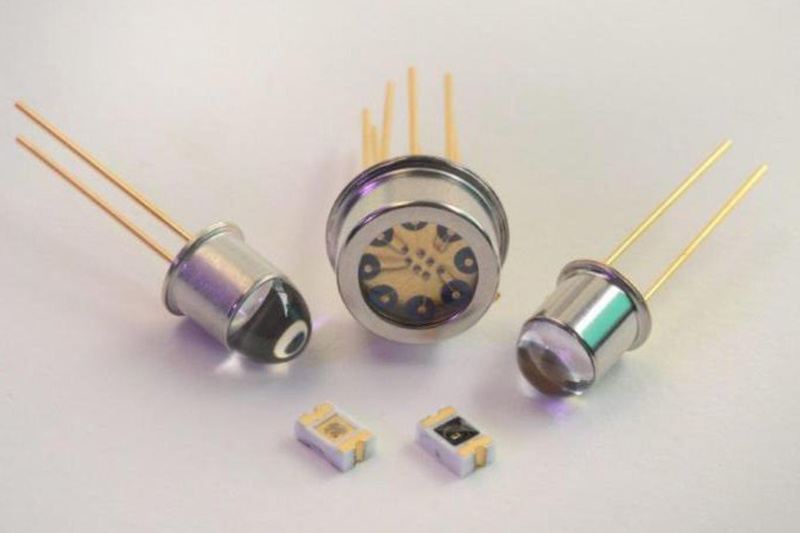

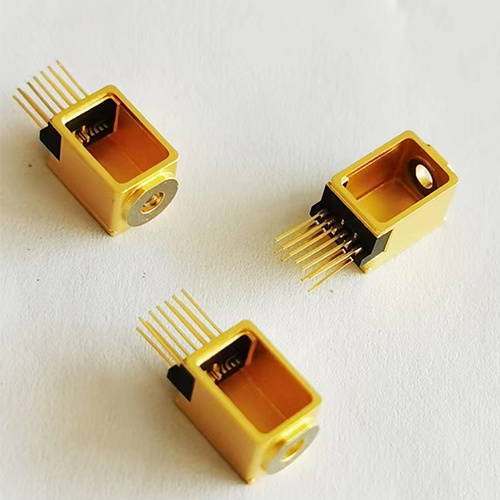

Product application

Precision alloy with specified tempreature coefficient of linear expansion are a series of fixed expansion alloys that can match soft glass and ceramics with different expansion coefficients within a given temperature range by adjusting the nickel content. The expansion coefficient and Curie point increase with the increase of nickel content. This group of alloys is a widely used sealing structural material in the electric vacuum industry. It is widely used in aerospace, precision instrument accessories, etc.

Chemical composition of Alloy

Grade Chemical Composition % C P S Mn Si Cu Cr Mo Ni Co Fe ≤ Kovar 0.03 0.020 0.020 0.50 0.30 0.20 0.20 0.20 28.5-29.5 16.8-17.8 Bal Alloy 33

(Ceramvar)0.03 0.020 0.020 0.50 0.30 - - - 32.1-33.6 14-15.2 Bal Invar 0.05 0.02 0.02 0.2-0.6 - - - - 35-37 - Bal Alloy 42 0.05 0.02 0.02 0.8 0.3 - - - 41.5-52.5 - Bal Alloy 48 0.05 0.015 0.015 0.4 0.3 4.5-5.5 - - 46-48 - 45.72-49.5 Heat treatment regime

Grade Heating tempreature ℃ atmosphere Keeping time h Cooling method Kovar 900±20

1100±20Protective atmosphere or vacuum 1 h

15minCool down to 200℃ at a speed of ≤5℃/min and take out of the furnace Alloy 33

(Ceramvar)900±20 Protective atmosphere or vacuum 1h ≤5℃/min Cooling speed to 200℃ and then take out of the oven Invar 840±10 Protective atmosphere or vacuum 1h 315±10℃/h Keep warm for 1h and cool with the furnace and air cool Alloy 42 900±20 hydrogen 1h ≤5℃/min Cooling speed to 200℃ and then take out of the oven Coefficient of expansion

Grade α1/10-6℃-1 20-100 20-300 20-400 20-450 20-500 Kovar - - 4.6-5.2 5.1-5.5 - Alloy 33

(Ceramvar)- - 6.0-6.8 - 6.6-7.4 Invar ≤1.5 - - - - Alloy 42 - 4.0-5.0 - 6.5-7.5 - Alloy 48 9.2-10.1 9.3-9.9 - - Physical Properties

Grade Density Resistivity

at 20℃Thermal conductivity Elastic modulus Curie point (g/cm3) (Ωmm2/m) λ/ W/(m*℃) E/ Gpa Tc/ ℃ Kovar 8.2 0.48 3.7-3.9 138 430 Alloy 33

(Ceramvar)8.27 0.46 17.6 139 440 Invar 8.1 0.78 11 230 144 Alloy 42

8.12 0.61 14.6 147 360 Alloy 48 8.2 0.45 420 Physical Properties

Grade Tensile Strength Mpa Elongation

%(≥)Condition Kovar <585 30 Soft >850 - Hard Alloy 33

(Ceramvar)<570 32 Soft >700 - Hard Invar 274-450 35 Hard Alloy 42 <590 35 Soft >820 - Hard Supply category

Alloy grade Type Size Kovar, Invar, Alloy 33

(Ceramvar), Alloy 42, Alloy 48Wire Ø = 0.1-10 mm Strip W= 5-250 mm T ≥ 0.1 mm Sheet W= 20-1500 mm T= 0.1 - 50 mm Foil W= 5-100 mm T= 0.01-0.1 mm Bar Ø = 5-300 mm L= 50-1000 mm Pipe Customized according to requirements

Contact us so we can better understand you

Every customer has their own needs, their own standards to adhere to and their own projects with unique specifications. Cheng Yuan is a partner in finding the right solution first time.

Ask a question, request information or enquire whichever way best suits you. Live chat with an expert, use any of our forms or contact us by phone or email.

Related Products

Cheng Yuan

Alloy Material

We look forward to working with you to jointly promote the development of China's alloy material industry.

Telephone

Email us

For more information, please leave your message below.