Exploring the Benefits of Pure Nickel Sheets in Modern Manufacturing: Advancements, Applications, and Future Trends

Release time:

2025-12-11

Exploring the Benefits of Pure Nickel Sheets in Modern Manufacturing In the realm of modern manufacturing, materials play a pivotal role in determining the efficiency, durability, and overall success of production processes. Among these materials, **pure nickel sheets** stand out for their exceptional properties and versatility. As industries evolve, the demand for high-performance materials like

Exploring the Benefits of Pure Nickel Sheets in Modern Manufacturing

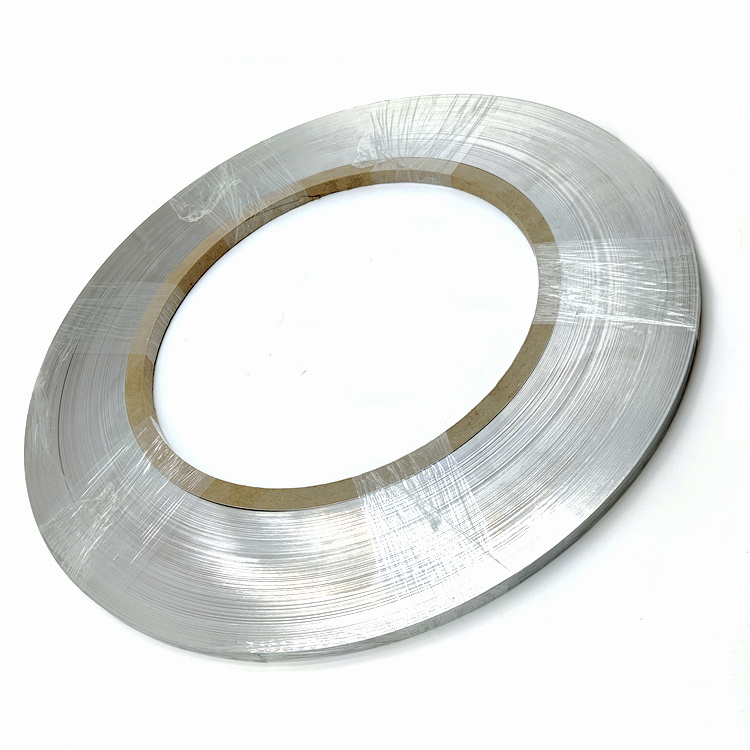

In the realm of modern manufacturing, materials play a pivotal role in determining the efficiency, durability, and overall success of production processes. Among these materials, **pure nickel sheets** stand out for their exceptional properties and versatility. As industries evolve, the demand for high-performance materials like nickel has surged, leading to innovative applications that push the boundaries of traditional manufacturing. This article aims to explore the myriad benefits of pure nickel sheets, their applications, and the future trends shaping their use in various sectors.

Table of Contents

- 1. Introduction to Pure Nickel Sheets

- 2. Key Properties of Pure Nickel

- 3. Applications of Pure Nickel Sheets in Various Industries

- 3.1 Aerospace Industry

- 3.2 Electronics and Electrical Applications

- 3.3 Chemical Processing

- 3.4 Automotive Manufacturing

- 4. Advantages of Using Pure Nickel Sheets in Manufacturing

- 5. Future Trends in the Use of Pure Nickel Sheets

- 6. Conclusion

- 7. Frequently Asked Questions (FAQs)

1. Introduction to Pure Nickel Sheets

Pure nickel sheets are thin, flat pieces of nickel metal that are extensively used in various manufacturing processes. With a composition of 99.9% nickel, these sheets exhibit remarkable characteristics like high ductility, excellent corrosion resistance, and outstanding thermal and electrical conductivity. As industries increasingly emphasize quality and performance, the demand for pure nickel sheets has escalated, leading to their widespread adoption in diverse applications.

2. Key Properties of Pure Nickel

2.1 Corrosion Resistance

One of the standout features of pure nickel sheets is their exceptional **corrosion resistance**. Nickel forms a protective oxide layer on its surface, preventing oxidation and degradation from environmental factors. This property makes pure nickel sheets ideal for applications in harsh environments, such as chemical processing and marine industries.

2.2 High Temperature Stability

Pure nickel exhibits excellent **high temperature stability**, maintaining its mechanical properties even at elevated temperatures. This attribute is crucial for applications that involve heat exposure, such as aerospace components and industrial furnaces. The ability to withstand high temperatures without deforming or losing strength positions pure nickel sheets as a preferred choice in demanding manufacturing conditions.

2.3 Mechanical Strength

Beyond corrosion resistance and temperature stability, pure nickel sheets offer impressive **mechanical strength**. Their tensile strength and durability ensure reliability in structural applications, making them suitable for critical components in various industries. The combination of strength and flexibility allows for easy fabrication and customization, catering to specific manufacturing needs.

3. Applications of Pure Nickel Sheets in Various Industries

3.1 Aerospace Industry

The aerospace industry significantly benefits from the use of pure nickel sheets, particularly in the construction of aircraft components. Their lightweight nature, combined with high strength and resistance to extreme temperatures, makes them ideal for critical applications such as turbine blades and exhaust systems. The reliability of pure nickel sheets is essential for ensuring safety and performance in aviation.

3.2 Electronics and Electrical Applications

In the electronics sector, pure nickel sheets serve as essential components for connectors, terminals, and batteries. Their excellent electrical conductivity ensures efficient power transmission, making them a preferred choice in the production of high-performance electronic devices. As technology advances, the demand for pure nickel in electronics continues to grow, driven by the need for miniaturization and increased functionality.

3.3 Chemical Processing

Chemical processing industries rely heavily on pure nickel sheets for equipment and piping systems. Their corrosion resistance makes them suitable for handling aggressive chemicals, ensuring longevity and safety in operations. From reactors to storage tanks, pure nickel sheets play a crucial role in maintaining the integrity of chemical processes, preventing leaks and failures.

3.4 Automotive Manufacturing

In the automotive industry, pure nickel sheets are used in various applications, including batteries and fuel cells. As the shift towards electric vehicles accelerates, the demand for nickel in battery production is increasing. Pure nickel's properties contribute to the efficiency and performance of batteries, making it a vital component in the transition to sustainable automotive solutions.

4. Advantages of Using Pure Nickel Sheets in Manufacturing

4.1 Cost-Effectiveness

Investing in pure nickel sheets can lead to long-term cost savings for manufacturers. While the initial purchase price may be higher than other materials, the durability and longevity of pure nickel reduce maintenance and replacement costs. Additionally, the efficiency gained from using high-quality materials often translates to increased productivity, offsetting initial expenditures.

4.2 Eco-Friendly Characteristics

As industries globally shift towards sustainability, pure nickel sheets offer eco-friendly advantages. Their ability to withstand harsh conditions leads to reduced waste and lower energy consumption in manufacturing processes. Moreover, nickel is recyclable, contributing to a circular economy and minimizing environmental impact. Utilizing pure nickel sheets aligns with the growing emphasis on responsible manufacturing practices.

5. Future Trends in the Use of Pure Nickel Sheets

The future of pure nickel sheets in manufacturing is bright, with several trends emerging that indicate continued growth and innovation. The increasing demand for sustainable materials in various industries is driving research into enhancing the properties of nickel. Innovations in production techniques, such as additive manufacturing, are expanding the possibilities for pure nickel applications. Furthermore, as electric vehicles and renewable energy technologies gain traction, the significance of nickel in these sectors will continue to rise, positioning it as a cornerstone of modern manufacturing.

6. Conclusion

Pure nickel sheets have become indispensable in modern manufacturing, offering a unique combination of properties that cater to the diverse needs of various industries. Their corrosion resistance, high-temperature stability, and mechanical strength make them ideal for applications ranging from aerospace to electronics and automotive manufacturing. As we advance into an era of sustainable and innovative manufacturing practices, the role of pure nickel is poised to expand, ensuring that it remains a vital material in future industrial developments.

7. Frequently Asked Questions (FAQs)

1. What are pure nickel sheets used for?

Pure nickel sheets are used across various industries, including aerospace, electronics, chemical processing, and automotive manufacturing. Their properties make them ideal for components that require durability and resistance to harsh conditions.

2. How do pure nickel sheets compare to other metals?

Pure nickel sheets offer superior corrosion resistance, high-temperature stability, and mechanical strength compared to many other metals. While they may come at a higher initial cost, their longevity and performance often justify the investment.

3. Are pure nickel sheets environmentally friendly?

Yes, pure nickel sheets are environmentally friendly due to their durability and recyclability. Their use in manufacturing can contribute to lower energy consumption and waste reduction, aligning with sustainable practices.

4. Can pure nickel sheets be easily fabricated?

Absolutely! Pure nickel sheets are highly ductile, allowing for easy fabrication and customization for specific manufacturing needs. They can be cut, formed, and welded to create various components.

5. What is the future of pure nickel in manufacturing?

The future of pure nickel in manufacturing looks promising, with increasing demand in sustainable technologies, particularly in electric vehicle and renewable energy sectors. Innovations in production techniques are likely to enhance its applications further.

SEO:

Cheng Yuan

Alloy Material

We look forward to working with you to jointly promote the development of China's alloy material industry.

Telephone

Email us

For more information, please leave your message below.