What are the corrosion resistant alloy materials

Release time:

2025-03-25

Corrosion resistant alloy mainly includes iron base, nickel base, titanium alloy, copper base, cobalt base and zirconium alloy six categories according to the specific application scenario to choose different material combinations.

Corrosion resistant alloy mainly includes iron base, nickel base, titanium alloy, copper base, cobalt base and zirconium alloy six categories according to the specific application scenario to choose different material combinations. The following are the specific categories and typical applications:

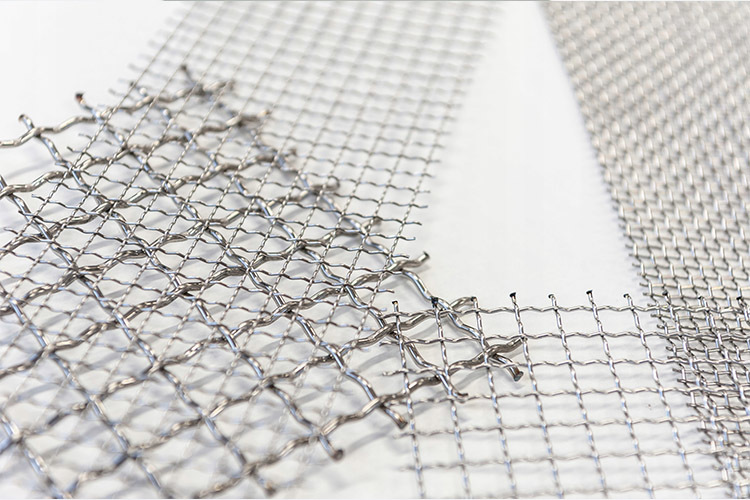

Iron base corrosion resistant alloy (stainless steel)

austenitic stainless steel (e.g., 316L) : containing 18%Cr-8%Ni, suitable for nitric acid and organic acid environment below 80℃, widely used in chemical equipment, food processing

duplex stainless steel : combined with the advantages of austenite and ferrite, the chloride ion corrosion resistance is 3 times that of ordinary stainless steel, used in harsh environments such as offshore platforms

Nickel-based corrosion resistant alloy

Hastelloy (such as C-276, B-3) : in boiling hydrochloric acid corrosion rate <0.1mm/ year, used in strong acid reactor, flue gas desulfurization system

Monel (e.g. Monel 400) : hydrofluoric acid and seawater corrosion resistance, offshore platform pipeline core material

Inconel series : Maintain oxidation resistance at 980℃, special material for aeroengine combustion chamber

Titanium and titanium alloys

industrial pure titanium : seawater corrosion rate <0.0025mm, ship propeller standard material

Ti-6Al-4V : Excellent biocompatibility, accounting for 62% of orthopedic implant device market

Ti-Pd alloy : The corrosion rate in boiling sulfuric acid is 90% lower than that of pure titanium

Copper base alloy

white copper (such as B30) : corrosion-resistant life of more than 15 years in the Marine atmosphere, cross-sea bridge cable protection material

aluminum bronze : the abrasion resistance of phosphate medium is 10 times higher than that of cast iron

Special alloy

cobalt-based alloy (such as Stellite 6B) : stable in sulfur flue gas at 650℃, special for waste incinerator nozzles

zirconium alloy (such as Zr-2) : nuclear reactor cladding material, to achieve 100,000 hours without corrosion record

The three major principles of material selection : medium matching (stainless steel is preferred for nitric acid), cost-benefit ratio (duplex steel replaces titanium alloy), and full cycle evaluation (including maintenance costs). Recent developments include environmentally friendly alloys, self-healing coating technology and intelligent monitoring integration.

Cheng Yuan

Alloy Material

We look forward to working with you to jointly promote the development of China's alloy material industry.

Telephone

Email us

For more information, please leave your message below.