Pure Nickel

If you need customized products, Contact US !

Category

Tag list

Pure Nickel

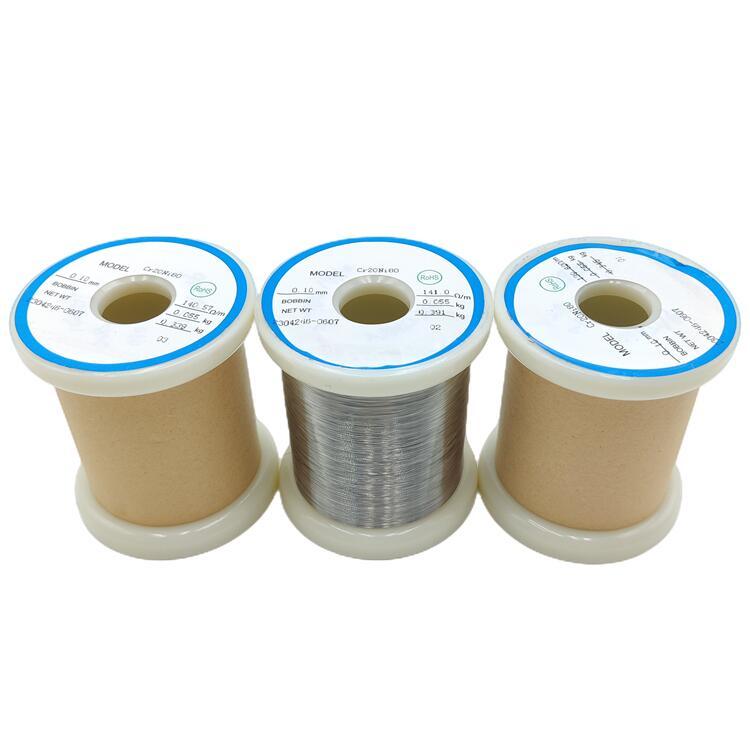

The product forms include wire, strip, plate, bar, wire mesh, powder, pipe, etc. Click to view.

Category

Tag list

- 详细描述

-

Product application

Pure Nickel has the characteristics of acid and alkali resistance, especially its outstanding alkali corrosion resistance, which makes it the main raw material for making various strong alkali resistance equipment. At the same time, it also has excellent corrosion resistance to salt media such as carbonate, nitrate, sulfate, chloride and acetate. In addition, it also has good processing performance, high electric vacuum performance, and stable performance in the atmosphere, fresh water and sea water. Therefore, the Ni200/ Ni201 wire, strip, sheet, bar, and tube are widely used in batteries, alkali production, chemical industry, mechanical and electronic industries, etc. Its strong anti-corrosion ability makes it indispensable in materials such as food, rayon and caustic that need to ensure product purity.

Chemical composition%:

Grade

Ni+Co

As

Bi

C

Cd

Cu

Fe

Mg

Mn

Ni201

Ni200

≥99,9

≥99,5

≤0,001

≤0,002

≤0,001

≤0,02

≤0,01

≤0,1

≤0,001

≤0,002

≤0,015

≤0,1

≤0,04

≤0,1

≤0,01

≤0,1

≤0,002

≤0,05

P

Pb

S

Sb

Si

Sn

Zn

Impurity

Ni201

Ni200

≤0,001

≤0,002

≤0,001

≤0,002

≤0,001

≤0,005

≤0,001

≤0,002

≤0,03

≤0,15

≤0,001

≤0,002

≤0,005

≤0,007

≤0,1

≤0,5

Mechanical properties of Strip

Material condition

Tensile strength,

Mpa (kgf / mm²), not less than, gradeselongation,

% not less than

gradesNi201; Ni200 Ni201; Ni200

δ10

δ5

Soft

390 ( 40)

32

35

1/2 Hard

440 ( 45)

10

12

Hard

540 ( 55)

2

3

Mechanical properties of Wire

Material conditionTensile strength,

MPa (kgf / mm²), not less than, gradeselongation,

% not less than

gradesNi201; Ni200 Ni201; Ni200

δ10

δ5

Soft

390 ( 40)

32

35

1/2 Hard

440 ( 45)

10

12

Hard

540 ( 55)

2

3

Resistivity:0.087 μOhm*m Density:8.9g/cm³

Due to its stable operation at high temperatures, nickel wire and strip are indispensable for production in the manufacture of electronic devices, navigation devices and high-precision electrical engineering.

Our company is characterized by a flexible pricing system and an individual approach to each client.

To clarify the technical characteristics, the possibility of manufacturing products, their cost and delivery conditions, you can contact our managers.Supply form and specification

Alloy grade Form Specification Ni201; Ni200

Wire Diameter=0.025mm~10mm Ni201; Ni200 Strip Width=1~600mm Thick=0.1~3.0mm Ni201; Ni200 Foil Width=5~120mm Thick=0.01~0.1mm Ni201; Ni200 Bar Diameter=3~100mm Length=50~1000 Ni201; Ni200 Plate Thickness :0.5mm~20mm;Width:50mm~1000mm

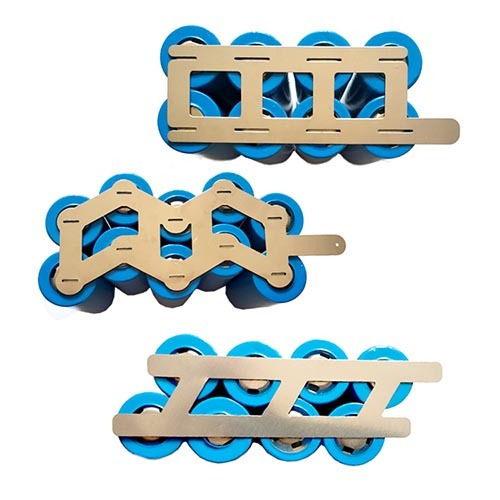

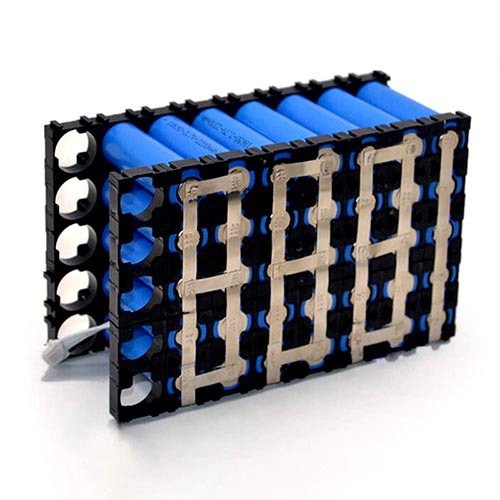

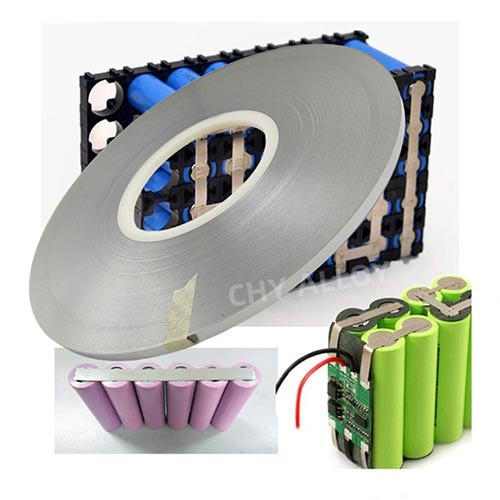

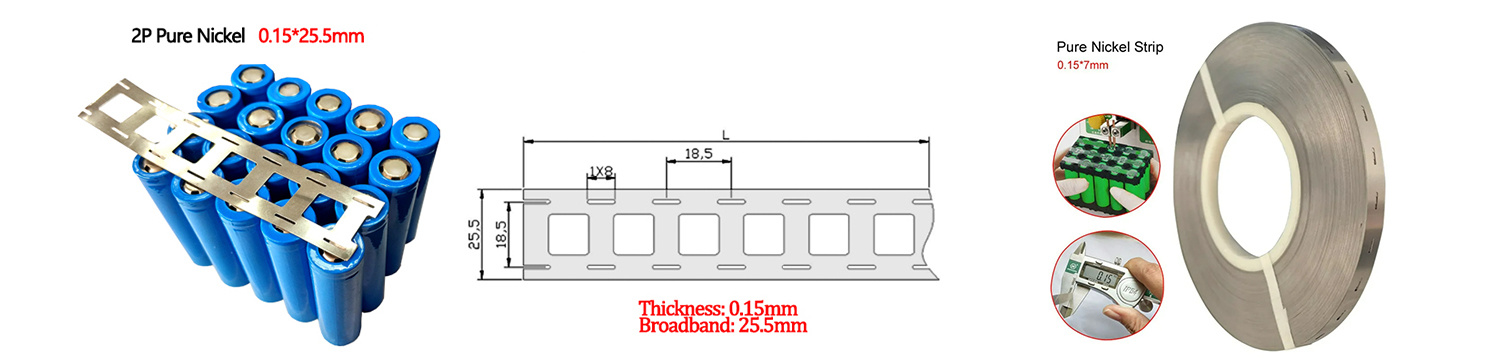

Length:500mm~6000mmWe also supplied the punched battery pack directly for the battery like 18650 21700 26650 32650 32700. we supply 1p,2p, 3p,4p,5p types. What’s more, we accept the new design and can making new punched mold for new design.It mainly used in lithium batteries, battery ear, metal stamping parts, electric vehicles, nickel batteries,tele-communications, electric vacuum, special bulbs and other industries.

Type

Nickel StripDiminsion(mm) Cell spacing

(mm)Width

(mm)Dimension of

the Square

hole(mm)Nickel-Plated

steel strip-Length

of per kg(m)Pure nickel

strip-Length of

per kg(m)With holder Without holder 1P 18650 0.15*7*18.4 18.4 7 - 128.3 112.6 √ 0.15*7*19 19 - 127.9 112.1 √ 0.15*7*19.5 19.5 - √ 0.15*7*20.25 20.25 - 127.6 111.9 √ 2P 18650 0.15*26*19(13.5*13.5) 19 26 12*12 47.2 41.4 √ 0.15*27*19.5(12*14.5) 19.5 27 12*14.5 48.9 42.9 √ 0.15*27*19.75(12.5*12.5) 19.75 12.5*12.5 47 41.2 √ 0.15*27*20.25(13.5*13.5) 20.25 13.5*13.5 48.9 42.9 √ 2P 18650 0.15*25.5*18.4(11*12.5) 18.4 25 11*12.5 48.9 42.9 √ Dislocation 2P 18650 0.15*25.5*18.4(8*9.5) 18.4 8*9.5 41.1 36.1 √ Dislocation 2P 18650 0.15*25.5*19.5(8*9.5) 19.5 8*9.5 38.6 33.8 √ 3P 18650 0.15*44.5*18.4(11*12.5) 18.4 44.5 11*12.5 27.4 24 √ 0.15*45*19(12*12) 19 45 12*12 29.1 25.5 √ 0.15*47.5*20.15(12.65*12.65) 20.15 47.5 12.65*12.65 27.4 24 √ 0.15*47.5*20.25(13.5*13.5) 20.25 13.5*13.5 29.4 25.7 √ 4P 18650 0.15*63*18.5(11*12.5) 18.5 63 11*12.5 21.6 18.9 √ 0.15*64*19(12*12.2) 19 64 12*12 21 18.4 √ 0.15*67.95*20.15(12.65*12.65) 20.15 67.95 12.65*12.65 19.6 17.2 √ 0.15*67.7*20.15(13.5*13.5) 20.25 67 13.5*13.5 21.3 18.7 √ 5P 18650 0.15*83*19(12*12) 19 83 12*12 16.4 14.4 √ 0.15*88.1*20.15(12.65*12.65) 20.15 88.1 12.65*12.65 19.7 17.3 √ 0.15*87.9*20.25(13.5*13.5) 20.25 87.9 13.5*13.5 16.7 14.6 √ 6P 18650 0.15*102*19(12*12) 19 102 12*12 13.5 11.9 √ 0.15*108.25*20.15 20.15 108.25 12.65*12.65 12.6 11 √ 0.15*87.9*20.25(13.5*13.5) 20.25 108.1 13.5*13.5 13.7 12 √ 7P 18650 0.15*121*19(12*12) 19 121 12*12 11.5 10 √ 0.15*128.4*20.15(12.65*12.65) 20.15 128.4 12.65*12.65 10.7 9.4 √ 0.15*128.3*20.25(13.5*13.5) 20.25 128.3 13.5*13.5 11.6 10.2 √ 8P 18650 0.15*140*19(12*12) 19 140 12*12 10 8.7 √ Pure Nickel welding wire

ERNi-1

Commonly used for welding of pure nickel (such as Ni200, Ni201) materials, such as chemical containers and pipelines made of pure nickel. In the welding of pure nickel materials, ERNi-1 can ensure that the weld has corrosion resistance and mechanical properties similar to those of the parent material.

Chemical composition

ERNi - 1 Nickel(Ni) Titanium(Ti) Aluminium(Al) Manganese(Mn) Iron(Fe) Silicon(Si) ≥93% 2.0~3.5% ≤1.5% ≤1.0% ≤1.0% ≤0.75% Copper(Cu) Carbon(C) Sulphur(S) Phosphorus(P) GY'S + Other ≤0.25% ≤0.15% ≤0.015% ≤0.003% ≤0.5% Mechanical properties

Performance Parameters

ERNi - 1

Yield Strength (MPa)

260

Tensile Strength (MPa)

460

Elongation (%)

28

Melting Point (℃)

1435 - 1445

Welding Current Parameters (2.6x300 specification, flat welding, A)

50 - 70

Welding Current Parameters (3.2x350 specification, flat welding, A)

60 - 90

Welding Current Parameters (4.0x350 specification, flat welding, A)

80 - 120

Supply status and specifications

Grade Form

Specifications and dimensions

ERNi - 1

Welding wire

DIA:0.8mm、1.0mm、1.2mm、1.6mm、2.0mm、2.4mm、3.2mm Coil Weight:15kg,20kg Welding rod

DIA:1.2mm 1.6mm 2.0mm、2.5mm、3.2mm、4.0mm、5.0mm 5 kgs per box

Contact us so we can better understand you

Every customer has their own needs, their own standards to adhere to and their own projects with unique specifications. Cheng Yuan is a partner in finding the right solution first time.

Ask a question, request information or enquire whichever way best suits you. Live chat with an expert, use any of our forms or contact us by phone or email.

Related Products

Cheng Yuan

Alloy Material

We look forward to working with you to jointly promote the development of China's alloy material industry.

Telephone

Email us

For more information, please leave your message below.